UHP graphite electrode price is of concern to many industries and electric arc furnace steel production and other industries. Because UHP graphite electrodes are key conductive raw materials used in high-temperature processes such as electric arc furnace steel production. Manufacturers pay attention to electrode prices in order to ensure that costs are controlled during the production process, improve production efficiency and maintain good profit levels.

Table of Contents

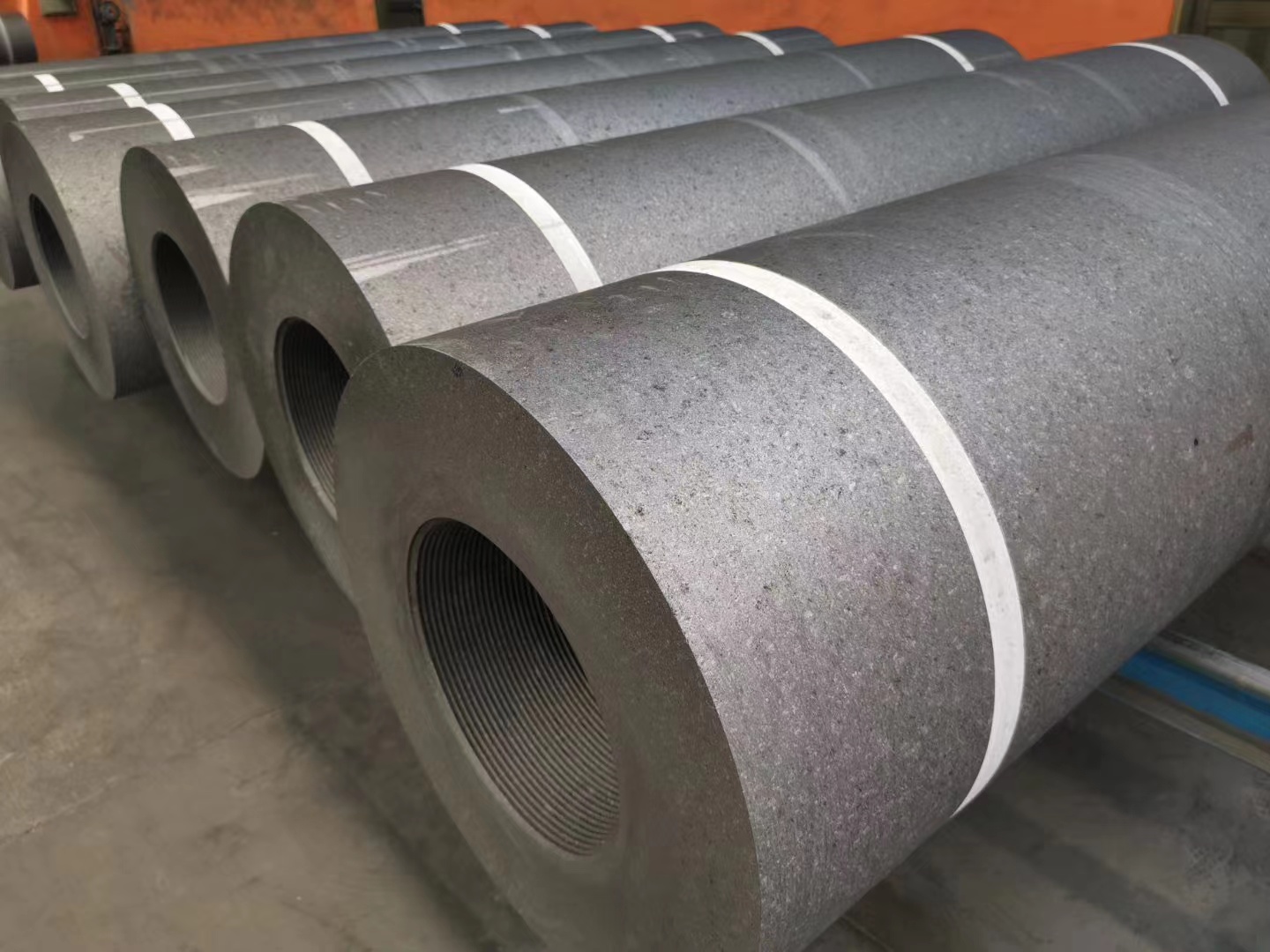

ToggleWhat is a graphite electrode?

A graphite electrode is a carbon-based electrode used in electric arc furnaces (EAFs) for steel and metal production. They generate an electric arc that heats and melts raw materials in the furnace. These electrodes are essential in eaf steelmaking as they provide the electrical energy required to achieve high temperatures for metal melting and refining. With their ability to withstand extreme temperatures, mechanical stress, and chemical reactions, graphite electrodes are indispensable in modern steel production.

In recent years, due to the continuous innovation of electric furnace steelmaking technology, higher requirements have been put forward for graphite electrodes used in eaf steelmaking. For example, the emergence of high-power or ultra-high-power electric furnace steelmaking is incredible. It can shorten the smelting time of our electric furnace by 56% and save more than 22% of electricity per ton of steel. Finally, increase the output by 1.3 times. To meet the needs of this steelmaking method, new high-power and ultra-high-power graphite electrodes have emerged.

UHP Graphite Electrode Price influencing factors

Raw material cost: Graphite electrodes are mainly made of petroleum coke and needle coke. Fluctuations in the prices of these raw materials will affect the overall production cost of graphite electrodes.

Supply and Demand: The balance of market supply and demand can significantly affect prices. If demand exceeds supply or supply chains are disrupted, prices may rise.

Energy costs: The production of graphite electrodes involves high-temperature processes, and the roasting and graphitization processes require large amounts of electricity. Changes in energy prices can affect overall manufacturing costs.

Quality and specifications: Needle coke content is different, ranging from 30% to 100%, and graphite electrode prices are different. Customers typically pay a premium for electrodes that meet strict quality standards.

Market Conditions: Overall economic conditions and market dynamics can affect prices. Factors such as economic growth, industrial activity, and global trade tensions may impact the graphite electrode market.

Features

- The specific resistance is low, so it can introduce a current that is 25%-40% higher than that of RP grade

- Small coefficient of thermal expansion, so the resistance to rapid cooling and rapid heating is good

- The mechanical strength is greater than that of regular power graphite electrodes

- Oxidation loss is slight, and the electrode consumption during eaf steelmaking is about twice as low as that of RP grades.

Application

The production of high-power and ultra-high-power graphite electrodes uses needle coke as raw material. Needle coke is a high-quality carbon raw material, and its addition dramatically improves the performance of electrodes. The products can meet the needs of various UHP Electric Arc Furnaces (EAF) and Ladle Furnaces (LF) steelmaking.

We need multiple dipping and roasting in the production process to increase the graphitization temperature. And the binder and impregnating agent should be improved accordingly.

How to use?

- Please dry the wet UHP graphite electrode before use.

- Please remove the protective foam cover on the spare electrode hole. Then check whether the inner thread of the electrode hole is intact.

- Clean the spare electrode surface and the inner thread of the hole with compressed air.

- Please carefully screw the connector into the spare electrode end’s electrode hole.

- Please use the graphite spreader to screw the electrode holder into the electrode hole at the other end of the spare electrode.

- When connecting the electrodes, clean the nipples with compressed air when the two electrodes are 20-30cm apart.

- When twisting the it with a torque wrench, fully tighten it to the specified position. So that the gap between the two electrodes is less than 0.05mm.

Conclusion:

The price of UHP graphite electrode is affected by raw materials and supply market factors. Beacause they have revolutionized steel making, making it more efficient, flexible, and environmentally friendly. They have excellent electrical conductivity, heat resistance and mechanical strength and can use electric arc furnaces to convert raw materials into high-quality steel.

Steel manufacturers can maintain precise control over the steel-making process, ensuring the desired composition, purity, and properties. Moreover, the energy efficiency and reduced environmental impact of electric arc furnaces contribute to sustainable steel production.

steelmaking-1024x795.jpg)