EDM graphite electrode-if you are considering using it in your manufacturing process. It’s essential to know the properties of these electrodes and how they can affect your operation. In this blog post, we’ll look at some of the critical properties of the EDM graphite electrode and what you should keep in mind when using them.

Table of Contents

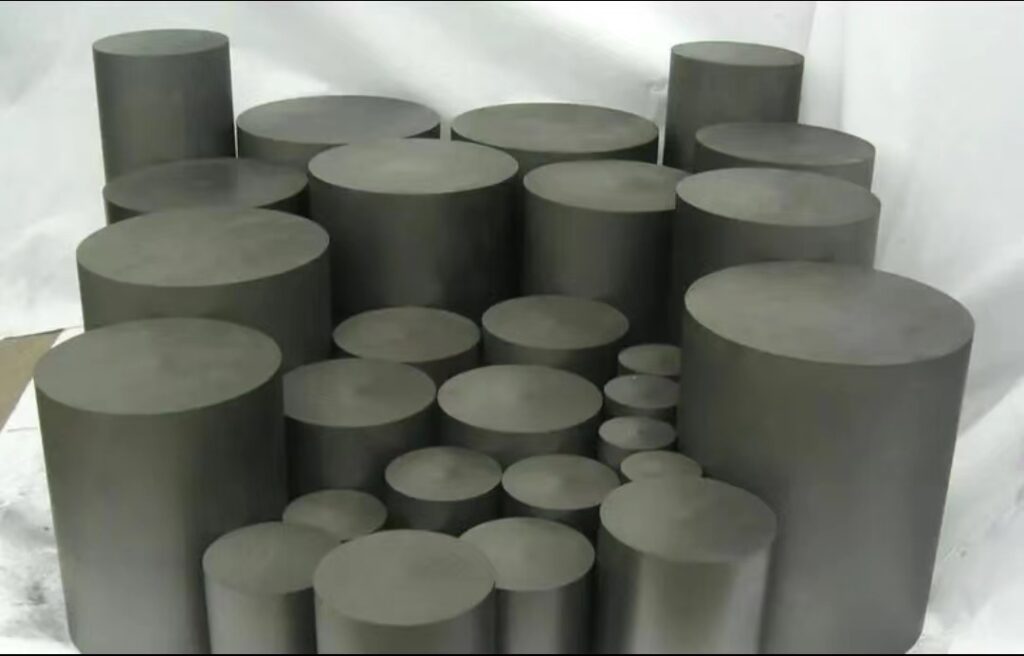

ToggleEDM graphite electrode is made of high-purity, fine-grain graphite.

It is specially crafted to provide superior benefits in EDM machining projects. With factories using this particular form of graphite, machine operators have greater control and precise control over EDM cuts, making the EDM process more accurate and efficient.

It is a wide range of materials. Manufacturers chose it for its ability to transmit energy while efficiently dissipating it at a uniform rate. In addition to these qualities, it also boasts increased thermal shock resistance, making them ideal for various EDM applications.

Specific Applications In electrical discharge machining (EDM)

EDM graphite electrode is remarkable tools that allow users to create exact shapes in metal parts. These versatile electrodes primarily used in EDM operations such as drilling, cutting, and trimming.

They are made from highly heat-resistant graphite material that can resist temperatures above new 2,500 degrees Celsius. They also have a non-conductivity component, meaning they don’t interfere with the EDM process and make it easier to achieve high accuracy when making complex shapes in hard metals.

Properties

EDM graphite electrode is some of the most reliable and robust components in the EDM machining process. With an impressive capability to withstand high temperatures and a notably high electrical conductivity.

It allows manufacturers to achieve greater accuracy in EDM machining, making for more efficient and higher-quality EDM work pieces. Not only does EDM electrode provide superior performance, but it is also more cost-effective than alternative options.

EDM (Electrical Discharge Machining) is a process of material removal from metals that works by eroding material using electrical sparks. At the same time, this is an efficient and cost-effective way to create intricate shapes.

It requires durable materials. For example, many alloys, such as stainless steel and tool steel, you can also use them in EDM due to their durability and wear resistance. Although these metal materials have good electrical conductivity and mechanical properties, their processing speed is very slow compared with graphite. Therefore, graphite is a better choice for graphite in the EDM process.

Advantage

Compared to other materials, EDM graphite electrodes’ main advantages are their excellent fine surface finishes and dimensional tolerances. Due to the high degree of graphitization, it has high processability and density and is very wear-resistant. Its integrity can be guaranteed even under the onslaught of electric sparks.

It can be used in many industries, including automotive and aerospace. Additionally, they provide a much higher quality surface finish than most other electrode materials. This means you can use them on more intricate cutting projects without damaging those cut parts.

Moreover, their high strength-to-weight ratio makes them ideal for accessing difficult areas or thin sections needing precise machining jobs.

Inclusion

The proportion of graphite as an electrode material for EDM applications has been increasing in recent years. So we should have a deep understanding of its characteristics. Due to its unique properties, graphite has become an ideal material for EDM applications. Graphite materials’ particle size, density, and machinability will directly affect the metal removal rate, electrode consumption, and surface accuracy. In general, the finer the particle size of the produced graphite, the smaller the electrode wear and the better the surface processing quality of the workpiece.