What Is Isomolded Graphite?

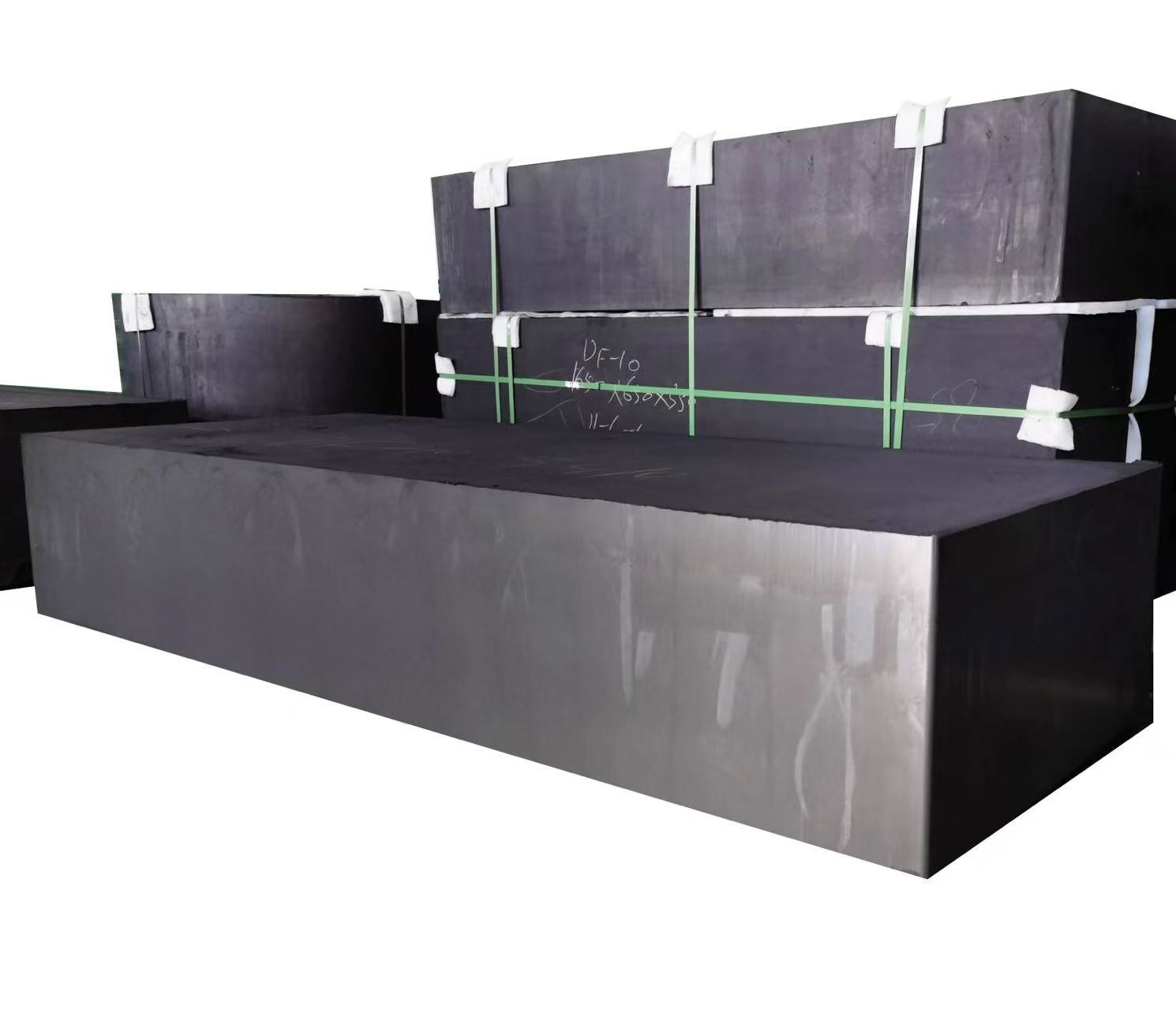

Isomolded graphite is high-density, fine-grained graphite made from isostatic pressing. Due to the uniform properties obtained by this process, this is a preferred method for some extreme applications where accuracy and uniformity are highly required. It has become a base material in high-performance industries, such as aerospace, nuclear, and semiconductor manufacturing, because of its unique structure and properties.

Table of Contents

ToggleIsomolded graphite is already a key component of several emerging technologies, due to its expanding demand for better mechanical and thermal properties over recent years. Isomolded graphite is essential for enhanced efficiency and longevity both in the electronics industries and aerospace industry.

Why Is It Important?

This ultimately makes isomolded graphite an important material for modern technology since its mechanical and thermal properties are superior to other materials. It is enabled to endure extreme temperatures, repel harmful chemicals, and produce elevated electricity and warmth conductivity. In recent years as industries demand material that will enhance performance and longevity isomolded graphite has continued to be the material of choice for many engineers and researchers.

This polymer’s fine-tuned manufacturing processes provide uniformity in properties, making it a go-to material for high-performance applications. Pure, fine-grained structure, which directly affects mechanical strength and resistance to thermal stress, make isomolded graphite more reliable than conventional graphite.

How Is Isomolded Graphite Made?

Raw Material Selection

It starts from the selection of high-purity carbon materials for maximal performance. Alloying elements will need to be minimized in order to keep the material’s excellent conductivity and structural recovery. Selecting the proper raw materials has a high impact on the final properties of the graphite, which makes this step essential.

The types of carbon precursors and their quality significantly influence the final properties of the resultant graphite. One area within chemical engineering is sourcing high-purity raw materials for development in industries such as aerospace and nuclear energy, where the performance of a material is non-negotiable.

Mixing and Blending

The chosen carbon powders are homogeneously combined with binder materials. This blend has to be highly regulated to ensure uniformity. The densification blending process also involves achieving the ideal density and porosity for optimal performance of the resulting isomolded graphite.

It is critical that the mixture is homogeneous or else any minor non-uniformity can affect the end mechanical properties of the graphite. Industry-leading blending equipment guarantees that raw materials are uniformly dispersed to deliver maximum strength and stability.

Isostatic Pressing Process

One of the key steps in isomolded graphite manufacturing is isostatic pressing. Traditional pressing methods apply force in one direction, whereas isostatic pressing applies pressure uniformly from all directions. This division, where room is equal to any point in any space, remove any structural weaknesses and thus density and regenerative potential is within the the same density. This process enables the production of highly accurate graphite components with very few defects.

Such technique enhances the strength of the material, making it strong even while facing harsh environmental conditions. The pressure applicators are uniformly distributed which makes isomolded graphite have higher mechanical uniformity which is important requirement in high performance applications.

Baking and Graphitization

This is high-drying baked to remove the binders and to increase the structural integrity of the material. At end the graphitization, takes place at even higher temperatures, usually above 2500 °C, where restructuring of carbon atoms takes place in a graphite crystal structure. It is a very important step because the electrical and thermal conductivity increases and the whole strengthening of the material.

Graphitization refines the crystallinity of the material, enhancing its electrical conductivity and mechanical stability. This cuts down porosity as well, helping the part last longer at high temperatures.

Final Processing and Machining

The material can machined into the necessary forms and sizes only after the graphitization process is completed. The precision cutting and grinding aspects of machining are used in advanced machining techniques to achieve the final product with high precision. This translates to an ideal material for situations where precision engineering is required.

Thanks to advanced machining, parts are cut within tight tolerances — minimizing the time and cost required to modify parts after they are produced. This accuracy is especially important in semiconductor production, where even a slight imperfection could result in product failure.

Key Properties of Isomolded Graphite

High Purity

Isomolded graphite with low impurity content is ideal for sensitive applications like semiconductor manufacturing and nuclear energy. Its high purity guarantees that it does not add foreign agents into sensitive processes, maintaining high operational efficacy and dependability of systems.

Fine Grain Structure

The fine-grain structure of the material provides superior mechanical and thermal properties. This is excellent for any immediate polishing applications with tight tolerances since it allows high precision machining.

High Strength

Isomolded graphite is relatively lightweight yet has high mechanical strength. This characteristic allows it to maintain strength in high-pressure settings and makes it ideal for demanding industrial environments.

Good Thermal Conductivity

Its great thermal conductivity allows the material to transfer heat efficiently, making it suited for high-temperature applications. This feature is especially beneficial in the aerospace and energy sectors, where heat elimination has to be effective and resourceful.

High Temperature Resistance

High temperature resistant (above 3000°C) and available as isomolded so that isomolded graphite can be used in metallurgy and nuclear industries.

Chemical Resistance

Data are provided on a range of corrosion-resistant plastics. Its resistance to acids and alkalis prolongs its life and service in harsh environments.

Applications of Isomolded Graphite

Aerospace and Defense

Application in rocket nozzles and heat shields.

Withstands extreme environment in space and a high-speed flight.

Ranging from high strength-to-weight ratios for optimum performance.

Semiconductor Manufacturing

Critical for silicon wafer production.

A high purity and precision chemical needed in semiconductor processing equipment.

And guarantee stable equipment performance in clean-room type environment.

Metallurgy and Foundries

Suitable for furnaces and crucibles at high temperatures.

Delivers effective thermal control when processing metals.

Improves the quality of metal castings and alloys.

Energy and Nuclear Industries

It is used as a neutron moderator in nuclear reactors.

Also provides fuel cell and battery technologies.

Helps to advance applications for renewable energy.

Electrical and Electronics

Used in electrical discharge machining (EDM) electrodes

Crucial for the production of high-duty electrical contacts.

AuT has reliability checkup on components on electronic circuits.

Glass and Ceramic Production

Make accurate molds to shape glass.

Improves the durability of ceramic processing tools.

Advantages of Isomolded Graphite Over Other Graphites

| Property | Isomolded Graphite | Extruded Graphite | Vibration Molded Graphite |

| Grain Size | Very Fine | Medium | Coarse |

| Density | High | Medium | Low |

| Strength | Very High | Medium | Low |

| Purity | High | Medium | Low |

| Machinability | Excellent | Good | Moderate |

Why Choose Isomolded Graphite?

Precision and Uniformity

Isomolded graphite has uniform properties, making it suitable for applications that require high accuracy – a characteristic it shares with few other types of graphite. Its consistency enables precision and repeatable manufacturing methodologies.

Longer Lifespan

Isomolded graphite components have longer life spans because of their high strength and durability, which reduces the need for maintenance and replacement. It results in lowering down the operational costs and better efficiency.

Superior Performance

Isomolded graphite beats all other graphite kinds in high-performance sectors, including the thermal, electrical, and chemical properties. It is an essential part of many industries because of its ability to remain structurally sound in extreme conditions.

Future Trends in Isomolded Graphite

Broader Industrial Use Cases

What is on the rise though, is the need for better-performing materials in industries as they change. Its use is growing in new applications including carbon-based nanotechnology, the field of biomedical engineering, and next-generation batteries.

New Technologies Utilizing Isomolded Graphite

Ongoing advancements in technology will drive isomolded graphite to be an essential material for new electronic devices, energy storage, and environmental applications. Researchers are investigating approaches to further improve its performance by adjusting its microstructure for additional strength and wear resistance.

Innovations in 3D Printing

Allows custom graphite parts to be manufactured with complex geometries.

Minimizes material waste but increases accuracy and fortitude.

Increases the scope of graphite applications in different industries.

Final Thoughts

The isomolded graphite remains an essential material in several industries due to its unmatched strength, durability, and precision. As technology advances, materials are demanded to perform better and isomolded graphite is at the forefront of this demand. Whether it be for aerospace, semiconductor manufacturing, or renewable energy, its unparalleled properties make it the go-to choice for advanced engineering solutions.

As a result of material science and technology continuing to emerge, isomolded graphite presents opportunity for our future in industry. The importance of this extraordinary material will continue to increase as new processing methods and novel applications are developed.