The difference between graphite electrode vs. copper electrode

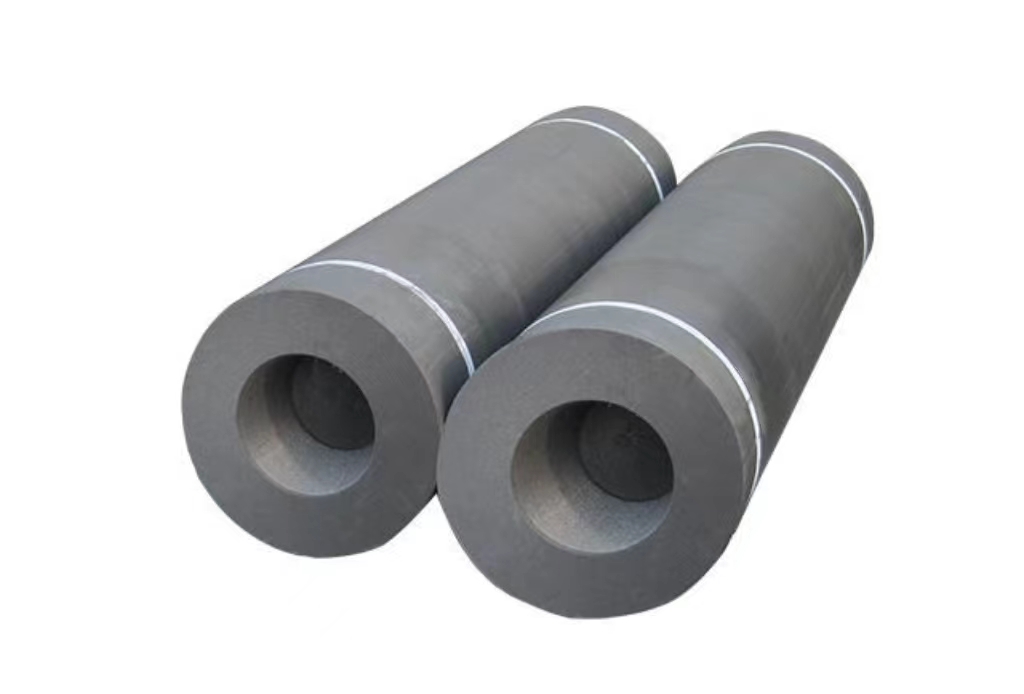

Graphite electrode vs. copper electrode-the industry’s two most commonly used electrode materials are graphite and copper electrodes. Graphite is a non-metal element, while copper is a metal. At the same time, graphite electrodes are use needle coke, petroleum coke and pitch coke as raw material, while copper electrodes are made of copper alloys.

Table of Contents

ToggleAdvantages and disadvantages of graphite electrodes

Graphite electrodes have several advantages. One of the main advantages is that they are resistant to high temperatures, but they are also highly resistant to thermal shock, which means they can withstand sudden temperature changes without cracking or breaking. They are also chemically inert, making them ideal for corrosive environments.

However, graphite electrodes also have some disadvantages. They are brittle than copper electrodes and may crack or break during use. It also has a lower electrical conductivity than copper electrodes, which results in slower processing times.

Advantages and disadvantages of copper electrodes

Copper electrodes have several advantages. They are excellent electrical conductors, are very durable, and have excellent thermal conductivity, which means they dissipate heat quickly, reducing the risk of thermal damage to the workpiece.

However, copper electrodes also have some disadvantages. They are not suitable for high temperature environments because their melting points are lower than graphite electrodes. There is also generally a higher risk of corrosion in corrosive environments.

Application fields

Graphite electrodes are often used in wide range industries that require high-temperature resistance. For example, for the electric arc furnace steel making, aluminum, and iron industries used for producing alloys and other high-temperature materials. People also use them in the glass and ceramic industries for melting and shaping materials.

Copper electrodes are often used in precision machining and cutting in the electronics industry. People also use them in the automotive industry to make engine parts and in the aerospace industry to make aircraft components.

Graphite vs Copper Electrode

Graphite and copper electrodes have different properties, making them suitable for different applications. When comparing these two materials in terms of cost, lifetime, and performance, we can observe the following:

Cost: Graphite electrodes are usually less expensive than copper electrodes.

Lifespan: Copper electrodes have a longer lifespan than graphite electrodes.

Performance: Graphite discharges two times faster than copper. Graphite material is not easily deformed, but copper electrodes are easily bent.

Which electrode is best for your industry?

The choice of electrode material depends on several factors, including industry type, production process, and specific application. Graphite electrodes are very suitable for high-temperature environments, while copper electrodes are more suitable for precision machining and cutting in the electronics industry.

Conclusion for Electrode Selection

In short, graphite electrodes are very suitable for high-temperature environments, while copper electrodes are more suitable for precision machining and cutting in the electronics industry.

It would help if you considered cost, lifetime, and performance when choosing between graphite and copper electrodes.

The choice of electrode material should be based on the specific requirements and industry of the application. Considering the factors outlined in this article, you can decide which electrode material is best for your industry.