Technology

- Home

- Technology

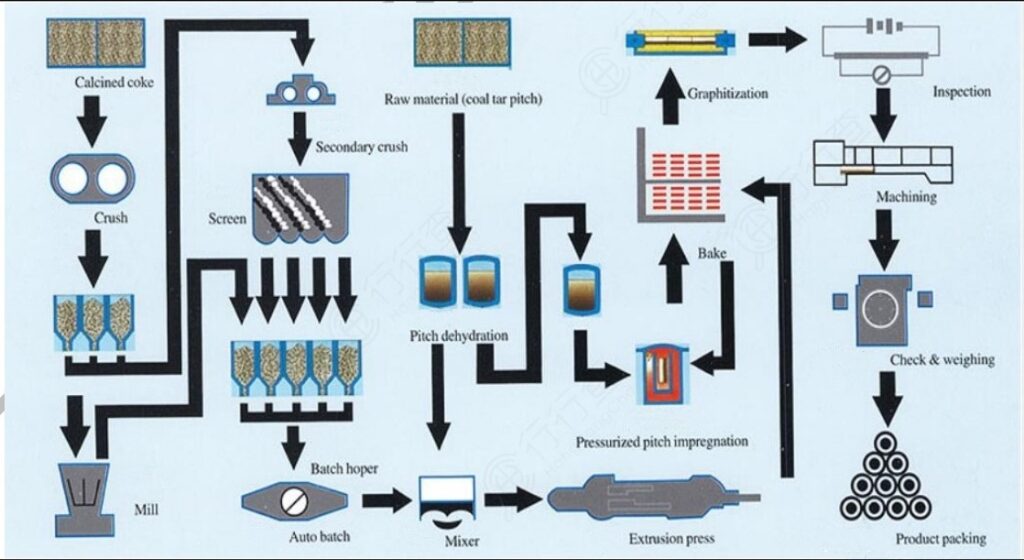

Graphite Electrode Manufacturing Process

Graphite electrode uses petroleum coke and needle coke as the main raw materials for manufacturing process. It is a high-temperature-resistant conductive material made through calcination, kneading, shaping, roasting, graphitization and machining. It is mainly used for electric arc furnace (eaf) steelmaking.

Graphite Electrode Usage Guide

The solid raw materials are mainly petroleum coke, pitch coke, and needle coke as aggregates.

Calcination is a process of heat treatment at high temperatures (1200-1500°C) under the condition of isolation from the air.

Crushing, screening, batching, and kneading of raw materials.

Forming, and extruding the kneaded paste.

5. Roasting is under the condition of being isolated from the air and protected by a medium, and then we heat the pressed product at a certain heating rate, which is such a process.

Impregnation is where we put the product in an autoclave, under a certain temperature and pressure. Finally the liquid impregnating agent is allowed to penetrate into the pores of the product.

Graphitization is a high-temperature heat treatment process. We convert thermodynamically unstable non-graphitic carbon to graphitic carbon by thermal activation.

Mechanical processing, we use CNC machine tools to process graphite raw materials into graphite products.

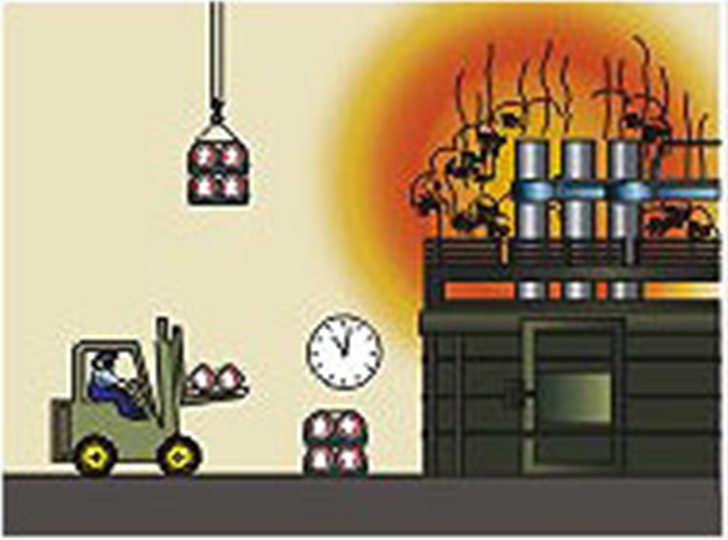

Please dry the graphite electrode next to the electric arc furnace before using it, and the temperature should be at most 150 degrees, and the time should be at least 24 hours.

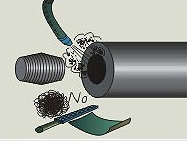

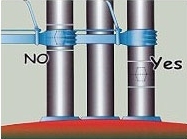

Connect the electrodes. You start by cleaning the threads of the electrode; then carefully screw the connector into one end of the electrode and the lifter connector into the other end of the electrode. Please be careful not to conflict with threads here. Also, we do not recommend screwing directly into the electrodes used to mount nipples on the stove.

Please do not clean the electrode threads with steel wool or metal brushes or abrasive cloths, and we recommend using compressed air free of oil and water.

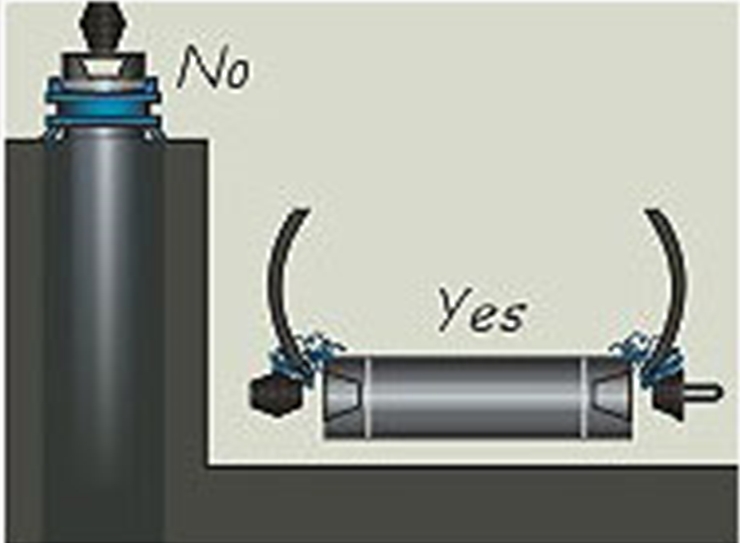

Please use the rotatable elastic hook. Also, place a soft support pad under the graphite electrode nipple to prevent damage to the threads.

Please use the elastic hook to hang the electrode on the furnace. Find the center first, then slowly move down and screw in gently. Finally, tighten it with the iron hoop.

Please use special calipers to tighten according to the specified torque. It can also be tightened to the specified torque by mechanical means or hydraulic or pneumatic equipment.

Please be sure to clamp the electrode clips within the two white warning lines. You need to clean the contact surface of the retainer and the electrode frequently, because it maintains good contact with the electrode. Please make sure that the cooling water jacket of the tool post does not leak.

Please do not place insulating materials in the furnace, so as not to break the electrodes. At the same time, please ensure that the working current of the electrode is consistent with the allowable current of the electrode in the manual.

Graphite Electrode Surface Quality

| Point | Requirement |

|---|---|

| 1. | Graphite electrodes should have a smooth surface with a maximum of two pieces or voids and no transverse cracks. If there are longitudinal cracks, they should be no wider than 0.3mm-1.0mm, and their combined length should not exceed 5% of the electrode’s circumference, with a limit of two cracks. |

| 2. | Regarding more than two pieces or voids. Graphite electrodes manufacturer ensures that the width is less than one-tenth of the circumference of the electrode. And the length is less than one-third of the length of the electrode. |

| 3. | The nipple, the nipple hole, and the electrode surface within 100mm from the bottom of the hole are not allowed to have voids and cracks. |

| 4. | There should be no more than one missing block on the thread of the nipple and the nipple hole. And the length should not be greater than 30mm. |

Note: Please check and accept your graphite electrodes and nipples according to electrode surfaces after receiving the goods to ensure their quality.