Extruded graphite, as an emerging high-performance material, has emerged in many industrial fields with its unique properties and wide applicability, and has become a force to be reckoned with.

Table of Contents

ToggleⅠ. Overview of extruded graphite

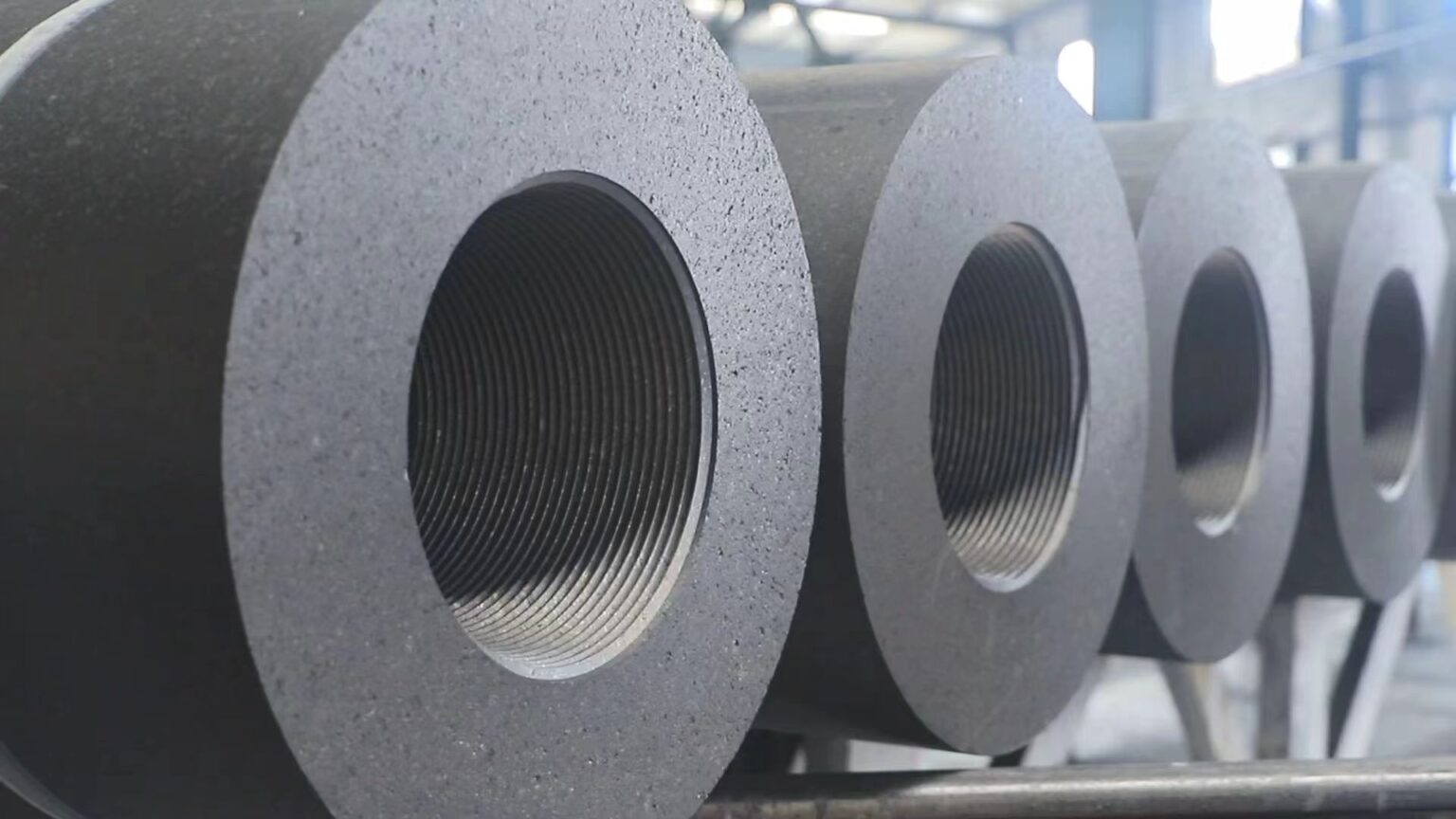

Extruded graphite is produced through an extrusion process in which a mixture of graphite and binder is forced through a mold to form the desired shape.

Extrusion method is semi-continuous production. After adding a certain amount of paste, several products (graphite rod, graphite block, graphite material) can be continuously extruded, so the production efficiency of extrusion method is much higher than that of pressing film method.

Ⅱ. Characteristics of graphite products

- Good adsorption.

Carbon with the hollow structure makes it feature good adsorption, therefore often used as adsorption material for adsorption of moisture, odor, etc.

- Good thermal conductivity, fast heat transfer, uniform heating, and fuel saving.

Baking trays and pots made of graphite heat up quickly, and the cooked food is evenly heated both from the inside and outside. Besides, the heating time is shorter, a pure taste is remained, and the original nutrition of the food is locked.

- Chemical stability.

Graphite with good chemical stability at room temperature cannot be corroded by any strong acid, strong alkali and organic solvent. Therefore, even if used for a long time, the loss of graphite can be very little, and what it needs is just to be scrubbed and cleaned.

III. Production process of extruded graphite

– Material preparation: selecting raw materials, such as natural flake graphite powder, asphalt coke, coal tar, etc.

– Pre-treatment: grinding, mixing, pre-oxidizing or chemical modification.

– Mixing and pressing: evenly mixing and pressing the processed materials under high pressure using special equipment to form the first embryo.

– Sintering solidification: sintering the primary embryo in a high-temperature environment to stabilize its structure.

– Post-processing: cutting, drilling, and other processing steps to make the desired shape and size of the product.

IV. Fields of Application

– Electronics: as a thermal insulation material in semiconductor manufacturing.

– Energy industry: neutron moderators for nuclear reactors, battery materials.

– Metallurgical industry: graphite molds, crucibles.

– Chemical industry: corrosion-resistant components, catalyst carriers.

– Brushes: Used in motors, generators and other equipment, as conductive and friction parts, with good wear resistance and conductivity.

– Others: aerospace, scientific research experiments, etc.

V. Comparison with different graphite production method

Isostatically pressed graphite:

Advantages: isotropic, high strength, high density, high purity and other characteristics.

Application Scenarios:

Semiconductor industry: used to manufacture single crystal furnace thermal field components, such as graphite crucibles, heaters, electrodes, etc., which can withstand high temperature and high vacuum environment to ensure the quality of crystal growth.

Solar photovoltaic industry: as a thermal field material for polysilicon ingot furnaces, improving the quality and efficiency of ingots.

EDM: The high conductivity and good machinability of isostatically pressed graphite make it suitable for the manufacture of EDM electrodes for machining high-precision molds and parts.

Molded graphite:

Advantages: ability of producing with complex shapes and high dimensional accuracy.

Application Scenarios:

Mechanical seal field: manufacturing all kinds of mechanical seal rings, such as pump seal rings, compressor sealing rings, etc., which can work under high speed, high pressure and other harsh conditions with good sealing performance.

Fuel Cells: Bipolar plates used to make fuel cells, their good conductivity and corrosion resistance help to improve the performance and life of fuel cells.

Synthetic graphite:

Advantages: adjusting properties according to needs, such as hardness, wear resistance, conductivity, etc.

Application Scenarios:

Lithium battery: As an anode material of lithium battery, it has high cycle performance and specific capacity. That means it can improve the energy density and service life of the battery.

Lubricants: The low coefficient of friction of synthetic graphite allows it to be used as a high-performance lubricant in aerospace, automotive and other applications to reduce friction and wear.

Ⅵ.Correct methods to use extruded graphite products

- Controlling environmental conditions

– Temperature: Most extruded graphite can remain stable in oxygen-free environments up to 3000°C, but in oxygenated environments, operating temperatures above 400°C should be avoided to prevent oxidation.

– Corrosive media: Certain acid-base solutions and halogen compounds can attack graphite, check media compatibility before use.

– Humidity: Although graphite is resistant to moisture, moisture may affect electrical properties and should be kept dry when stored.

- Processing and installation

– Non-ferrous tools should be used for cutting, drilling, etc., to avoid the introduction of impurities.

– Handle with care during installation to prevent cracks caused by impact or gravity.

- Cleaning and maintenance

– Use a soft cloth or brush to remove dust from the surface and avoid scratching the surface with hard cleaning tools.

– Regularly inspect for signs of wear or damage, and replace aging or damaged parts in a timely manner.

- Security Measures

– When used in contact with current conduction parts, make sure of well-connection to avoid current overload.

– Wear appropriate personal protective equipment when operating, especially when working in hot or hazardous gas environments.

- Storage Recommendations

– Store in a cool, dry place, away from chemicals and direct heat sources.

– If you do not use for a long time, please use moisture-proof packaging to reduce the impact of environmental factors.

- Precautions

– Although graphite itself is not flammable, spontaneous combustion can occur under certain conditions. Such as sparks from high-speed friction or prolonged exposure to high temperatures in an oxygen-rich environment.

– Do not store or use in a humid or environments containing strong oxidizing properties, which may accelerate oxidation or cause safety concerns.

VII. Future development potential in modern industry.

Currently, extruded graphite is not only improved in terms of density and strength, but also optimized in terms of corrosion resistance and thermal stability. And it will keep advancing to meet the market’s new needs.

In the future, the development of extruded graphite will focus more ontechnological innovation and the expansion of application fields. As the demand for high-purity graphite materials in the semiconductor industry increases, extruded graphite will focus more on improving its purity and processing accuracy. Technically, the focus will be on improving the thermal conductivity and mechanical strength of extruded graphite, for example through the development of new composite materials to enhance its properties. In addition, with the advancement of sustainable development goals, the production and application of extruded graphite will pay more attention to the use of environmentally friendly materials and design. At the same time, it reduces energy consumption and waste emissions in the production process.