In the field of materials science, graphite and carbon fiber have excellent properties and play an important role in many fields from aerospace to daily life. In-depth understanding of their properties, applications and market dynamics is of great significance for promoting the development of materials science.

Table of Contents

Toggle

Basic overview of graphite and carbon fiber

Graphite

Structure

It has a typical layered crystal structure. Each layer of it is connected by covalent bonds between carbon atoms, forming a hexagonal planar network structure. This makes the binding force between carbon atoms in the layer strong. The layers interact with each other through weaker van der Waals forces. This unique structure gives it many special properties, such as good lubricity. Because the van der Waals force between the layers is weak, the layers are easy to slide relative to each other. At the same time, it also has certain electrical conductivity, and electrons can move relatively freely within the layer.

The production process

Its production process is usually more complicated. It commonly use petroleum coke and asphalt coke as raw materials. First, you need pre-treat these raw materials to remove impurities. Then, it is calcined at high temperatures to make it initially graphitized. Then, after grinding, forming and other processes to make the desired shape. Finally, it is also necessary to carry out high temperature graphitization treatment to further improve the purity and crystallinity of graphite. Generally this high temperature process can reach 2500℃ -3000 ℃, in order to obtain graphite materials with excellent performance.

Carbon Fiber

Structure

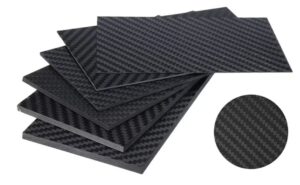

It is a high-strength and high-modulus fiber with carbon content of more than 90%. From the perspective of microstructure, the carbon atom arrangement of carbon fiber has a certain orientation. This shows a similar chaotic graphite structure, which makes it have high strength and modulus. The carbon atoms in carbon fiber are mainly bonded through covalent bonds to form a stable structural framework.

The production process

This is generally based on polyacrylonitrile (PAN) fiber, asphalt fiber or viscose fiber. Taking PAN-based carbon fiber as an example, the production process begins with the polymerization and spinning of the precursor filament. The PAN monomer is polymerized into a polymer, and the fiber is made through the spinning process. Then carry out the pre-oxidation treatment, and oxidize and cross-link the PAN fiber in the air at 200℃-300℃. To form a heat-resistant trapezoidal structure to prepare for subsequent carbonization. Then carbonization treatment, under the protection of 1000℃ -1500℃ inert gas, remove the non-carbon atoms in the fiber. So that the carbon content reaches more than 90%. Finally, carry out graphitization according to needs. And further improve the crystallinity and modulus of carbon fiber at high temperatures above 2000 ℃ to improve its performance.

Properties comparison of graphite vs carbon fiber

Mechanical properties

Strength

Carbon fiber’s strength is extremely high, the tensile strength of high-performance carbon fiber exceeds 3500MPa, and the special carbon fiber even exceeds 7000MPa. You can often use it in aerospace and other structural parts that bear high tensile forces. Due to the weak van der Waals force between layers, graphite is easy to slip. And the tensile strength of ordinary graphite is only dozens of MPa, which is lower than that of carbon fiber.

Modulus

The modulus of carbon fiber is high, generally in the 230-480GPa, the high modulus of over 600GPa. The force deformation is small, the shape stability is good. The modulus of graphite is usually several GPa to tens of GPa, and the resistance to deformation is much worse than that of carbon fiber. It is difficult to apply in scenarios with high deformation requirements.

Physical properties

Density

The density of carbon fiber is 1.7-2.0g /cm³. It is a lightweight material with obvious advantages in the field of aerospace and automotive lightweight. The density of graphite is 2.09-2.23 g/cm³, which is slightly higher than carbon fiber. And its application is limited in scenarios with strict weight restrictions.

Electrical conductivity

Graphite conductivity of 104 – 105 S/m, commonly used in the electronic field as battery electrode, brush and so on. Carbon fiber has a relatively low electrical conductivity of 102 -104 S/m. But you can improve it by special treatment to meet specific needs.

Thermal conductivity

Graphite has good thermal conductivity and anisotropy, and the parallel layer thermal conductivity reaches hundreds of W/(m·K). You can often use it in electronic equipment heat sinks. The heat conduction of carbon fiber is also anisotropic. The thermal conductivity along the fiber axis is 100-800W /(m·K), and the vertical direction is only 5-20W /(m·K).

Chemical properties

Corrosion resistance

Graphite has good corrosion resistance, can resist most acid and alkali erosion. And you can use it in the chemical industry to make corrosion resistant pipelines and reactor linings. Carbon fiber is stable in the general chemical environment and can withstand common acid and base solutions. But in special environments such as strong oxidizing acids, chemical reactions may cause performance degradation.

Oxidation resistance

Graphite and carbon fiber have good oxidation resistance at room temperature. However, as the temperature rises, graphite reacts obviously with oxygen above 400℃. And carbon fiber has obvious oxidation phenomenon around 300℃, limiting their application in high temperature aerobic environment. But the surface coating treatment can be improved to a certain extent.

Comparison of application fields: graphite vs carbon fiber

Graphite application fields

In the metallurgical industry, as a refractory material, like graphite crucible can withstand high temperature and chemical erosion. Graphite mold for casting industry to improve casting accuracy and surface quality. In the field of electronics, you can use it as an electrode and is also used to manufacture flexible heat sinks. In the nuclear industry, it acts as a moderator to ensure the stability of nuclear reactions. Besides, in the steelmaking industry, electrodes made of graphite are used as conductors to generate electric arcs to smelt steel or metal alloys.

Carbon fiber application fields

Aerospace field, with high strength, low density characteristics, you can use it to manufacture aircraft wings and other components, improve flight performance. In sporting goods, you can often use it to create high-end bicycles, golf clubs, etc., to improve quality. In the automotive industry, you can use it to manufacture body parts and transmission shafts to achieve lightweight and reduce energy consumption and emissions.

Cost and market analysis: graphite vs carbon fiber

Analysis of cost composition

The cost of graphite covers raw materials, energy consumption and equipment depreciation, etc..

Because of abundant raw materials and mature process, the overall cost is low. The proportion of raw fiber cost in carbon fiber cost is large, the price of high-performance PAN raw fiber is high. And the production process energy consumption is large, the equipment is expensive, and the maintenance cost is high. These result in high production costs.

Market status and trend

The graphite market is mature, widely used, and the demand is stable. With the development of new energy and electronics industries, the demand for specific fields is still growing. Carbon fiber market rapid growth in recent years, aerospace, automotive lightweight and other high-end areas of increasing demand. Technological progress and scale expansion is expected to reduce costs, market prospects.

Buying Guide

When buying graphite, be sure to consider its purity, particle size and physical and chemical properties. Also choose the right supplier to ensure that the graphite products meet the application requirements, come with test reports and complete after-sales service.

Looking for high-performance graphite materials? Explore our high-quality graphite products, designed to more effectively help you improve the performance and competitiveness of your industrial products. Buy now.

Conclusions

Graphite and carbon fiber differ significantly in structure, performance, application and cost, and each plays a key role in different fields. In the future, they are expected to optimize performance and reduce costs. And you need to be reasonably select them according to demand in practical applications to maximize benefits.