Der Unterschied zwischen Graphitelektrode und Kupferelektrode

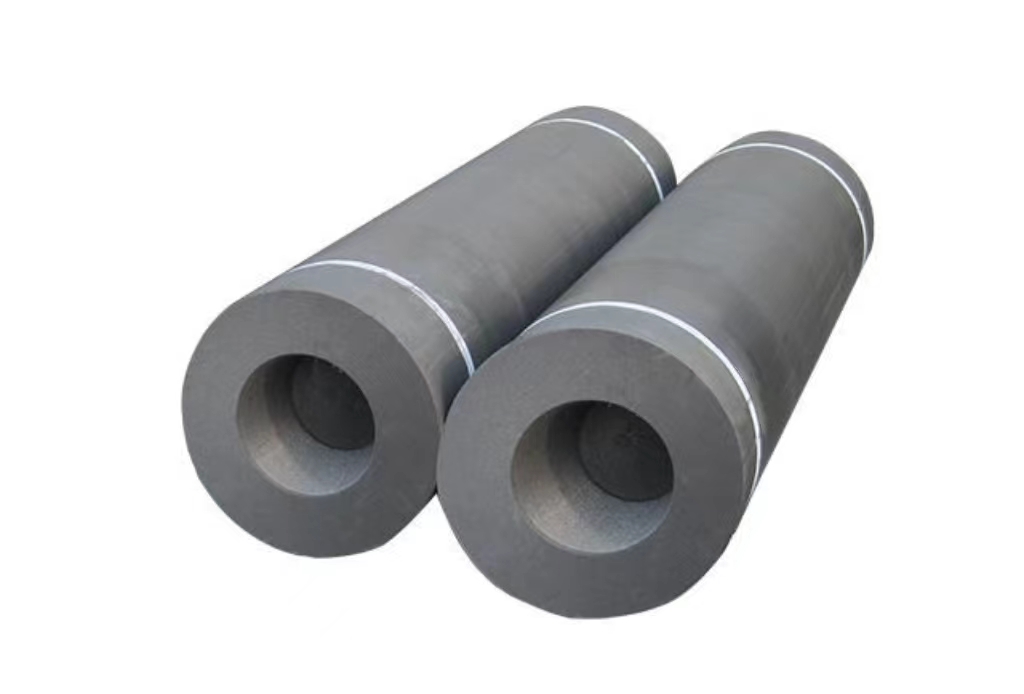

Graphitelektrode vs. Kupferelektrode - die beiden in der Industrie am häufigsten verwendeten Elektrodenmaterialien sind Graphit- und Kupferelektroden. Graphit ist ein nichtmetallisches Element, während Kupfer ein Metall ist. Gleichzeitig werden für Graphitelektroden Nadelkoks, Petrolkoks und Pechkoks als Rohmaterial verwendet, während Kupferelektroden aus Kupferlegierungen hergestellt werden.

Inhaltsübersicht

Umschalten aufVor- und Nachteile von Graphitelektroden

Graphit-Elektroden haben mehrere Vorteile. Einer der Hauptvorteile ist die hohe Temperaturbeständigkeit, aber auch die hohe Temperaturwechselbeständigkeit, d. h. sie können plötzliche Temperaturschwankungen ohne Rissbildung oder Bruch überstehen. Außerdem sind sie chemisch inert, was sie ideal für korrosive Umgebungen macht.

Graphitelektroden haben jedoch auch einige Nachteile. Sie sind spröder als Kupferelektroden und können bei der Verwendung reißen oder brechen. Außerdem haben sie eine geringere elektrische Leitfähigkeit als Kupferelektroden, was zu langsameren Verarbeitungszeiten führt.

Vor- und Nachteile von Kupferelektroden

Kupferelektroden haben mehrere Vorteile. Sie sind hervorragende elektrische Leiter, sehr langlebig und haben eine ausgezeichnete Wärmeleitfähigkeit, d. h. sie leiten die Wärme schnell ab, was das Risiko einer thermischen Beschädigung des Werkstücks verringert.

Kupferelektroden haben jedoch auch einige Nachteile. Sie sind nicht für Hochtemperaturumgebungen geeignet, da ihr Schmelzpunkt niedriger ist als der von Graphitelektroden. Außerdem besteht in korrosiven Umgebungen generell ein höheres Korrosionsrisiko.

Anwendungsbereiche

Graphitelektroden werden häufig in einer Vielzahl von Industriezweigen eingesetzt, die eine hohe Temperaturbeständigkeit erfordern. Zum Beispiel für den elektrischen Lichtbogenofen StahlerzeugungSie werden in der Aluminium- und Eisenindustrie zur Herstellung von Legierungen und anderen Hochtemperaturwerkstoffen verwendet. Sie werden auch in der Glas- und Keramikindustrie zum Schmelzen und Formen von Materialien verwendet.

Kupferelektroden werden häufig für die Präzisionsbearbeitung und das Schneiden in der Elektronikindustrie verwendet. Sie werden auch in der Automobilindustrie zur Herstellung von Motorenteilen und in der Luft- und Raumfahrtindustrie zur Herstellung von Flugzeugteilen verwendet.

Graphit- vs. Kupferelektrode

Graphit- und Kupferelektroden haben unterschiedliche Eigenschaften, die sie für verschiedene Anwendungen geeignet machen. Beim Vergleich dieser beiden Materialien in Bezug auf Kosten, Lebensdauer und Leistung können wir Folgendes feststellen:

Kosten: Graphit-Elektroden sind in der Regel billiger als Kupferelektroden.

Lebenserwartung: Kupferelektroden haben eine längere Lebensdauer als Graphitelektroden.

Leistung: Graphit entlädt sich zwei Mal schneller als Kupfer. Graphitmaterial lässt sich nicht so leicht verformen, während Kupferelektroden leicht zu verbiegen sind.

Welche Elektrode ist die beste für Ihre Branche?

Die Wahl des Elektrodenmaterials hängt von mehreren Faktoren ab, darunter die Art der Industrie, der Produktionsprozess und die spezifische Anwendung. Graphitelektroden eignen sich sehr gut für Hochtemperaturumgebungen, während Kupferelektroden eher für die Präzisionsbearbeitung und das Schneiden in der Industrie geeignet sind. Elektronik Industrie.

Schlussfolgerung für die Elektrodenauswahl

Kurz gesagt, Graphitelektroden sind sehr gut für Hochtemperaturumgebungen geeignet, während Kupferelektroden eher für die Präzisionsbearbeitung und das Schneiden in der Elektronikindustrie geeignet sind.

Es wäre hilfreich, wenn Sie bei der Wahl zwischen Graphit- und Kupferelektroden Kosten, Lebensdauer und Leistung berücksichtigen würden.

Die Wahl des Elektrodenmaterials sollte sich an den spezifischen Anforderungen und der Branche der Anwendung orientieren. Unter Berücksichtigung der in diesem Artikel genannten Faktoren können Sie entscheiden, welches Elektrodenmaterial für Ihre Branche am besten geeignet ist.