Tecnologia

- Início

- Tecnologia

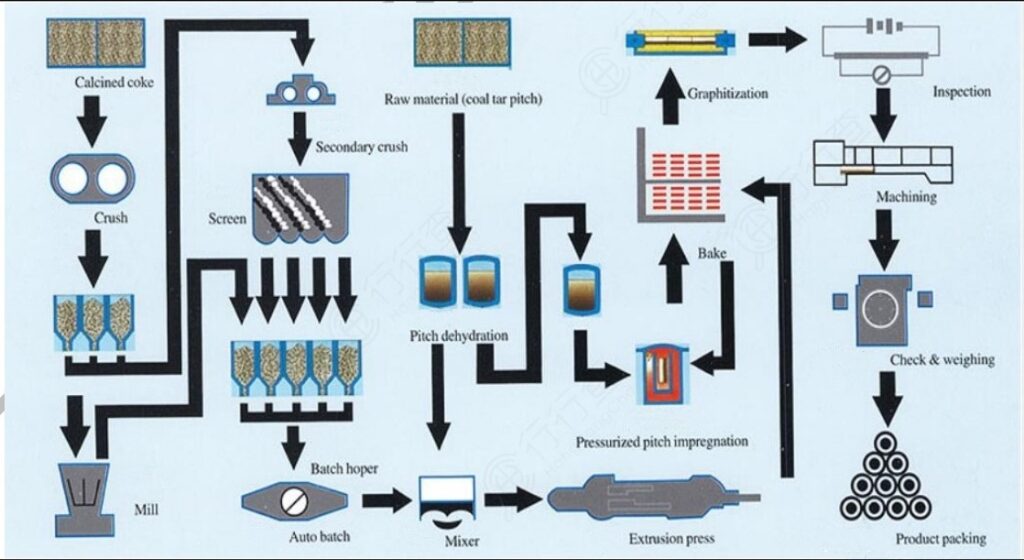

Processo de fabricação de eletrodos de grafite

O eletrodo de grafite usa coque de petróleo e coque de agulha como as principais matérias-primas para o processo de fabricação. É um material condutor resistente a altas temperaturas feito por meio de calcinação, amassamento, modelagem, torrefação, grafitização e usinagem. É usado principalmente na fabricação de aço em fornos elétricos a arco (eaf).

Guia de uso de eletrodos de grafite

As matérias-primas sólidas são principalmente coque de petróleo, coque de breu e coque de agulha como agregados.

A calcinação é um processo de tratamento térmico em altas temperaturas (1200-1500°C) sob a condição de isolamento do ar.

Trituração, peneiramento, dosagem e amassamento de matérias-primas.

Formação e extrusão da pasta amassada.

5. A torrefação é feita sob a condição de ser isolada do ar e protegida por um meio, e então aquecemos o produto prensado em uma determinada taxa de aquecimento, que é esse processo.

A impregnação é quando colocamos o produto em uma autoclave, sob uma determinada temperatura e pressão. Por fim, permite-se que o agente impregnante líquido penetre nos poros do produto.

A grafitização é um processo de tratamento térmico de alta temperatura. Nós convertemos materiais não grafitizados termodinamicamente instáveis em materiais de alta qualidade. carbono em carbono grafítico por ativação térmica.

No processamento mecânico, usamos máquinas-ferramentas CNC para processar matérias-primas de grafite em produtos de grafite.

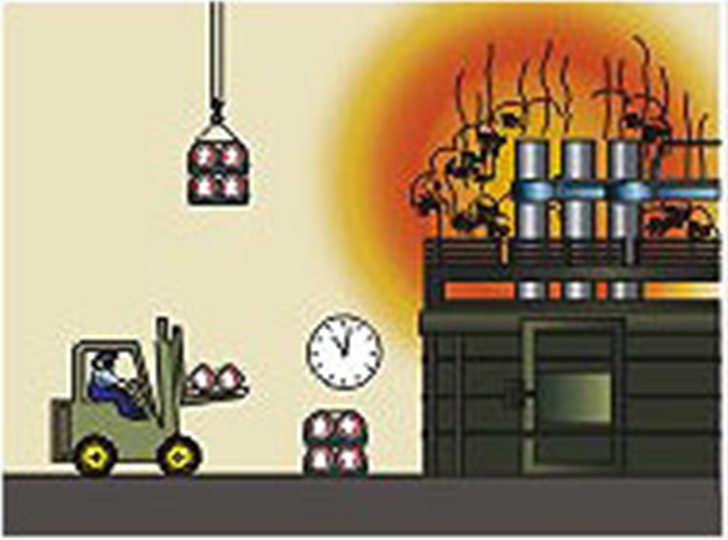

Por favor, seque o eletrodo de grafite ao lado do forno elétrico a arco antes de usá-lo, e a temperatura deve ser de no máximo 150 graus, e o tempo deve ser de pelo menos 24 horas.

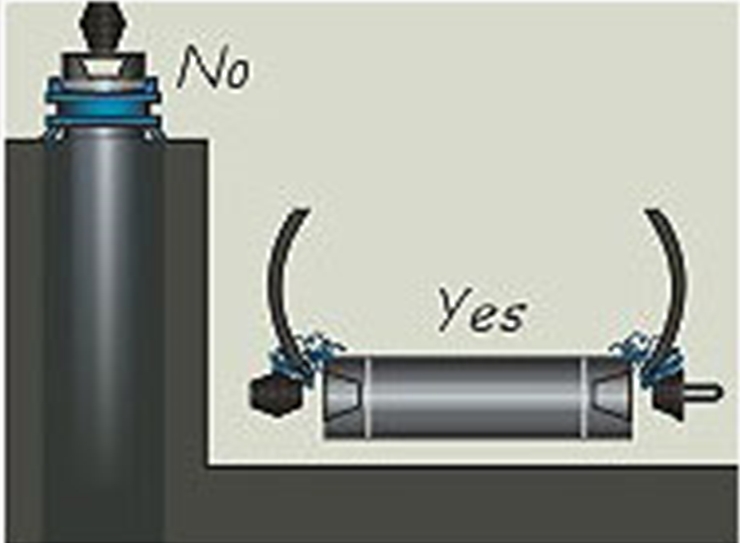

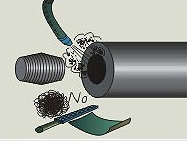

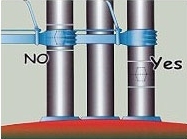

Conecte os eletrodos. Comece limpando as roscas do eletrodo; em seguida, parafuse cuidadosamente o conector em uma extremidade do eletrodo e o conector do levantador na outra extremidade do eletrodo. Tenha cuidado para não entrar em conflito com as roscas aqui. Além disso, não recomendamos parafusar diretamente nos eletrodos usados para montar bicos no fogão.

Não limpe as roscas do eletrodo com palha de aço, escovas de metal ou panos abrasivos, e recomendamos o uso de ar comprimido livre de óleo e água.

Use o gancho elástico giratório. Além disso, coloque uma almofada de apoio macia sob o eletrodo de grafite mamilo para evitar danos às roscas.

Use o gancho elástico para pendurar o eletrodo no forno. Primeiro, encontre o centro e, em seguida, mova-o lentamente para baixo e aparafuse-o com cuidado. Por fim, aperte-o com o aro de ferro.

Use calibradores especiais para apertar de acordo com o torque especificado. Ele também pode ser apertado com o torque especificado por meios mecânicos ou equipamentos hidráulicos ou pneumáticos.

Certifique-se de prender os clipes do eletrodo dentro das duas linhas brancas de aviso. É necessário limpar a superfície de contato do retentor e do eletrodo com frequência, pois isso mantém um bom contato com o eletrodo. Certifique-se de que a camisa de água de resfriamento do poste da ferramenta não esteja vazando.

Não coloque materiais isolantes no forno para não quebrar os eletrodos. Ao mesmo tempo, certifique-se de que a corrente de trabalho do eletrodo seja consistente com a corrente permitida do eletrodo no manual.

Qualidade da superfície do eletrodo de grafite

| Ponto | Requisito |

|---|---|

| 1. | Os eletrodos de grafite devem ter uma superfície lisa com no máximo dois pedaços ou espaços vazios e sem rachaduras transversais. Se houver rachaduras longitudinais, elas não devem ser maiores do que 0,3 mm a 1,0 mm, e seu comprimento combinado não deve exceder 5% da circunferência do eletrodo, com um limite de duas rachaduras. |

| 2. | Com relação a mais de duas peças ou espaços vazios. O fabricante de eletrodos de grafite garante que a largura seja inferior a um décimo da circunferência do eletrodo. E o comprimento seja inferior a um terço do comprimento do eletrodo. |

| 3. | O niple, o orifício do niple e a superfície do eletrodo em um raio de 100 mm a partir da parte inferior do orifício não podem apresentar vazios ou rachaduras. |

| 4. | Não deve haver mais de um bloco faltando na rosca do niple e no orifício do niple. E o comprimento não deve ser maior do que 30 mm. |

Observação: Verifique e aceite seus eletrodos e bicos de grafite de acordo com as superfícies dos eletrodos após o recebimento das mercadorias para garantir sua qualidade.