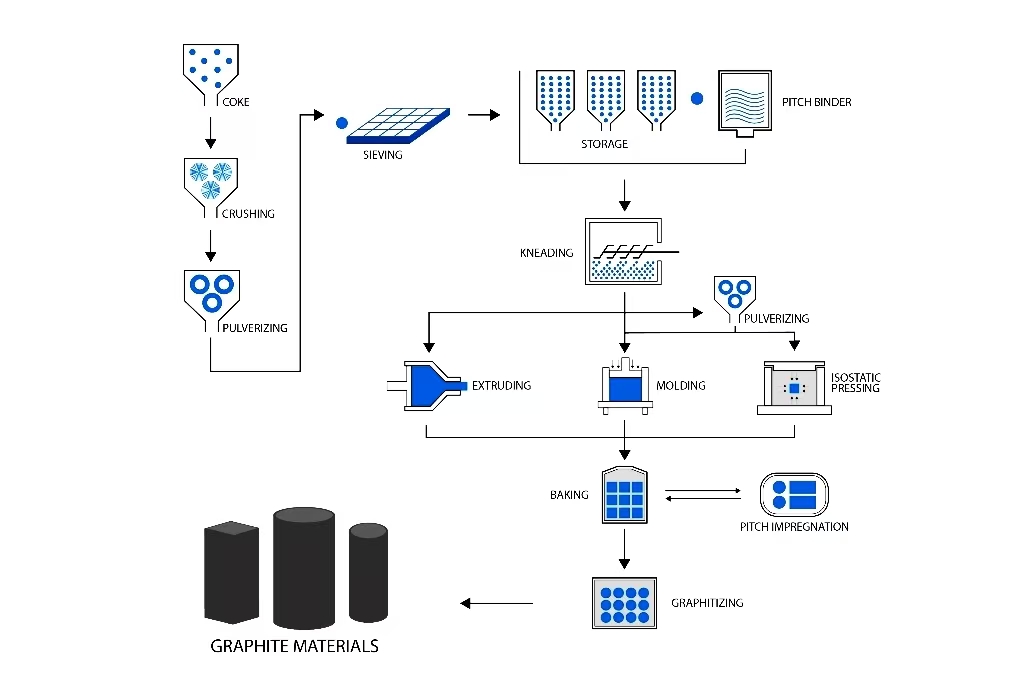

Il processo di produzione della grafite comprende due tipi: grafite naturale e grafite sintetica artificiale. Il processo di produzione prevede diverse fasi importanti per garantirne la qualità, in relazione all'applicazione dei materiali di grafite nell'industria. In questo blog vi illustreremo l'intero processo di produzione della grafite.

Indice dei contenuti

ToggleChe cos'è la grafite?

La grafite è il carbonio naturale. È nera, setosa e scivolosa. È contenuta in matite, batterie e lubrificanti. È il materiale grafitico con la più alta conducibilità elettrica e termica. È inoltre stabile a temperature elevate, il che ne aumenta l'impiego nell'industria.

Abbiamo due modi per ottenere la grafite. Si può estrarre dalle miniere della terra, oppure si può produrre sinteticamente.

La grafite naturale viene estratta, macinata e lavorata per produrre una struttura densa. Tra queste, la grafite in fiocchi ha le caratteristiche di resistenza alle alte temperature e buona conduttività. Le sue proprietà dipendono dal luogo di provenienza e dalle modalità di lavorazione.

Il processo di produzione della grafite sintetica è di qualità superiore, più uniforme e più flessibile. Le materie prime vengono lavorate in più fasi per ottenere il prodotto finale. Questo processo richiede molte fasi, ma il risultato finale è di qualità. La grafite sintetica può essere prodotta in base a specifiche e viene quindi utilizzata per applicazioni specifiche e critiche, ad esempio per le batterie e l'elettronica.

Materie prime: Processo di produzione della grafite Cosa serve

Si comincia con le materie prime. Ad esempio, sono necessari materiali di carbonio come coke di petrolio, needle coke o pitch coke. Si tratta di materie prime fondamentali in quanto sono una fonte di carbonio ad alto contenuto, essenzialmente l'elemento base della grafite. Il coke di petrolio deriva dalla raffinazione del petrolio, mentre il needle coke è un prodotto di qualità superiore utilizzato nella produzione di elettrodi di grafite.

Questi coke vengono poi cotti e combinati con leganti. I leganti creano una connessione tra le particelle che porta alla coesione. I leganti più comuni sono la pece di catrame di carbone o la pece di petrolio, che danno vita a un prodotto resistente e durevole. A seconda dell'uso finale del prodotto di grafite, possono essere necessari anche additivi come la silice o il ferro. Tutti i materiali sono necessari per ottenere il prodotto finale di grafite e influenzano la definizione delle caratteristiche.

Fase 1: miscelazione e lavorazione delle materie prime di grafite

In una prima fase, le materie prime vengono mescolate. La polvere di coke viene frantumata molto finemente, in modo che il legante possa mescolarsi in modo molto uniforme con il coke. Quindi la polvere di coke viene mescolata con il legante a temperature elevate. Il legante tiene insieme il tutto, rivestendo ogni particella di coke e facendo in modo che si attacchi. In questo modo si evita una miscelazione eterogenea dei componenti e si ottengono costituenti facilmente modellabili.

Anche il grado di miscelazione è un altro aspetto. In questo caso la miscela non è omogenea e può causare alcuni punti deboli nel prodotto di processo. La temperatura e la tempistica devono essere attentamente controllate per garantire una distribuzione uniforme del legante. Questa combinazione è fondamentale per la forma del prodotto, in quanto influisce sulla densità, sulla porosità e sulla resistenza della grafite.

Fase 2: Formare la forma

Stampaggio:

L'impasto viene versato in uno stampo e compresso. Questa tecnica tende a essere buona per la costruzione di forme solide semplici (blocchi, dischi, ecc.). Lo stampaggio è ottimo per la produzione di grandi volumi in cui è necessario produrre sempre la stessa cosa.

Estrusione:

Il materiale viene estruso attraverso una filiera per produrre barre lunghe, tubi o altre forme allungate. Nel caso degli elettrodi di grafite, ad esempio, dove sono richieste sezioni trasversali coerenti, si adotta l'estrusione. È possibile stabilire un processo di produzione costante di grafite in continuità ed è appropriato per oggetti che devono ottenere figure particolari.

Pressatura isostatica:

Questo processo consente di realizzare forme più complesse senza tensioni interne, utilizzando una pressione uguale su tutto il perimetro. È utilizzato per produrre grafite specificamente densa con caratteristiche omogenee. Quando il prodotto finale deve resistere a pressioni elevate o alla produzione di forme complesse e precise, la compattazione viene solitamente eseguita con la pressatura isostatica.

Fase 3: cottura del prodotto

Deve essere cotto per eliminare l'umidità e fissare il prodotto dopo la formatura. Questo processo è noto come cottura o carbonizzazione. Si tratta di mettere il prodotto modellato in un forno, dove il prodotto viene riscaldato ad alta temperatura, di solito a circa 1.000-1.200°C, e l'azione di drogaggio avviene nel rilascio della pirolisi.

Possono essere necessarie settimane per la cottura, quando la precipitazione è grande e spessa. Viene collegato a qualcosa che porta la temperatura lentamente per non romperlo o danneggiarlo in altro modo. Una volta cotta la miscela, il materiale si asciuga e si indurisce fino a raggiungere la durezza e la densità necessarie. È uno dei processi più importanti del processo di produzione, poiché svolge un ruolo fondamentale nella formazione della resistenza, della densità e della porosità del prodotto. Una volta cotto, si parla di "materiale carbonizzato" o "manufatto in carbonio".

Fase 4: Impregnazione

La fase successiva è l'impregnazione per migliorare la qualità del prodotto carbonizzato. Impregnazione - riempimento con un'altra sostanza dei pori del prodotto cotto, utilizzato per aumentarne la densità e la resistenza.

Impregnazione dell'asfalto:

Si riempiono i pori del materiale carbonizzato con l'asfalto. L'impregnazione di asfalto migliora la densità e la resistenza meccanica del prodotto. Questo ha anche l'effetto finale di ridurre la porosità del materiale, che si traduce in un prodotto non solo più durevole ma anche più resistente all'usura.

Impregnazione di resina:

Il prodotto è stato impregnato con resina sintetica in impregnazione di resina. Questo metodo viene utilizzato per ottenere un prodotto con buone proprietà di isolamento elettrico o quando è necessaria una maggiore resistenza a determinati prodotti chimici. L'immersione in resina rende inoltre la grafite più forte e più resistente.

Impregnazione del metallo:

In alcuni casi, per l'impregnazione si utilizzano anche metalli come il rame o l'argento. L'impregnazione metallica aumenta la conducibilità elettrica e termica. Viene quindi utilizzata nelle applicazioni che richiedono un materiale altamente conduttivo, come alcuni componenti elettrici.

Una volta impregnato, il prodotto viene solitamente cotto ancora una volta per polimerizzare il materiale impregnante. Questa seconda fase di cottura aiuta anche la sostanza impregnante ad aderire meglio al materiale carbonizzato, ottenendo un prodotto più resistente e durevole.

Fase 5: grafitizzazione

La quinta fase è la grafitizzazione. Nella grafitizzazione, i produttori riscaldano il prodotto carbonizzato in un forno a resistenza a temperature estremamente elevate, in genere superiori a 3000 °C. Modificando la struttura atomica del carbonio, si spera di trasformarlo in grafite. A queste alte temperature, gli atomi si riorganizzano in una struttura cristallina, chiamata strati di atomi di carbonio che definiscono la grafite.

Inoltre, le alte temperature eliminano qualsiasi impurità residua, rendendo il prodotto altamente puro. Grafitizzazione è un processo importante durante il quale la grafite viene definita con proprietà variabili di bassa lubrificazione, elevata capacità di conduttore elettrico e alta resistenza al calore. Il prodotto realizzato è quindi un materiale molto più resistente e stabile rispetto al materiale carbonizzato e può essere utilizzato in applicazioni ingegneristiche molto impegnative.

Fase 6: Lavorazione

La forma e le dimensioni finali della grafite vengono lavorate dopo la grafitizzazione. La grafite è più morbida di quasi tutti gli altri ingredienti industriali, quindi è facile da lavorare. Il prodotto ottenuto può richiedere il taglio, la foratura o la fresatura in base a determinate dimensioni e requisiti.

Gli elettrodi di grafite utilizzati nei forni elettrici ad arco devono essere sottoposti a lavorazioni di alta precisione per garantire un buon funzionamento. In base all'applicazione, il processo di lavorazione ci offre anche la possibilità di produrre forme e design personalizzati. Molte parti in grafite non possono essere lavorate a macchina e possono presentare filettature, fori o altre lavorazioni di precisione che richiedono operatori qualificati e attrezzature specializzate.

Controllo qualità: Controllo del prodotto

Dopo la lavorazione, si procede all'ispezione. Il controllo della qualità è fondamentale nel processo di produzione della grafite sintetica, in quanto è necessario ottenere specifiche cruciali. I produttori devono completare i test su densità, resistenza, porosità, conduttività e altre specifiche per ogni lotto di materiali.

Vengono inoltre sottoposti a un'ispezione visiva per individuare eventuali difetti, come crepe, superfici irregolari o imperfezioni. Vengono utilizzate apparecchiature speciali per misurare la conduttività e la conducibilità termica del materiale. grafene. Questi test vengono utilizzati per affermare che il prodotto soddisfa le aspettative misurate da un punto di vista industriale e rispetta le esigenze e i desideri dei clienti target. Una produzione con garanzia di qualità assicura la costanza della qualità e impedisce la vendita di prodotti difettosi sul mercato.

Purificazione: Opzionale per l'alta purezza

A volte c'è bisogno di grafite ultrapura per applicazioni speciali, ad esempio nell'industria dei semiconduttori o dell'elettronica. In questo caso, si ricorre a un'ulteriore fase di purificazione per eliminare le impurità. Per quanto riguarda il processo di purificazione, i produttori generalmente eseguono un trattamento chimico o un trattamento termico ad alta temperatura.

La purificazione chimica utilizza acidi o altri agenti chimici per la soluzione dei componenti impuri. Nel trattamento termico ad alta temperatura, invece, la grafite viene riscaldata a temperature così elevate che le impurità possono evaporare (solidi). La grafite ad alta purezza, esattamente la grafite purificata, è impiegata in applicazioni quali reattori nucleari, batterie e alcuni componenti aerospaziali. Il suo nome ufficiale è grafite purificata o grafite di elevata purezza.

Riciclaggio dei rottami di grafite

La grafite è un materiale prezioso e il riciclaggio è un metodo fondamentale per la sua produzione. I produttori possono raccogliere, riciclare e utilizzare gli scarti di grafite. Se i produttori frantumano la grafite riciclata in polvere fine e la aggiungono alla miscela di materie prime, possono produrre nuovi prodotti di grafite o di carbonio.

Il riciclaggio della grafite promuove la sostenibilità e preserva le risorse. E riduce i costi, poiché la lavorazione della grafite riciclata costa meno dell'estrazione e della lavorazione di materie prime fresche. La grafite riciclata viene utilizzata in molti settori per ridurre l'impatto ambientale e aumentare la sostenibilità.

Applicazioni chiave della grafite sintetica

Elettrodi di grafite: Utilizzati nei forni elettrici ad arco, per fondere i rottami metallici. Sono sempre stati il cuore del siderurgia e altri settori di raffinazione dei metalli.

La grafite come materiale anodico: La grafite è attualmente l'unico materiale anodico utilizzabile nelle batterie agli ioni di litio. La sua grande conducibilità elettrica la rende un materiale adatto ad immagazzinare energia.

Grafite come espandibile: Questo tipo di piastrelle in grafite ha la funzione di ritardare il fuoco. La grafite espandibile si espande quando viene applicato il calore e forma uno strato isolante che impedisce efficacemente la propagazione del fuoco.

Lubrificanti e guarnizioni: Le proprietà lubrificanti della grafite la rendono ideale per i lubrificanti. Previene l'attrito e l'usura nei macchinari, contribuendo a prolungare la vita delle attrezzature.

Materiali refrattari: Le applicazioni ad alta temperatura, come i mattoni refrattari e i crogioli, sono realizzate in grafite stabile.

Elettronica / Semiconduttori: La grafite ad alta purezza viene comunemente utilizzata nella produzione di componenti elettronici e semiconduttori, dove sono richieste stabilità termica e conduttività stabile.

Conclusione

La qualità della grafite è determinata dalla miscelazione delle materie prime, dalla grafitizzazione e dalla lavorazione.

L'efficienza e la sostenibilità della produzione di grafite sono migliorate grazie al controllo di qualità, alla purificazione opzionale e al riciclo degli scarti di grafite. La sua produzione garantisce un prodotto di grafite uniforme e stabile per uso industriale, elettronico o di elevata purezza. Jinsun è una delle aziende leader nella produzione di grafite in Cina e siete sempre invitati a contattarci.