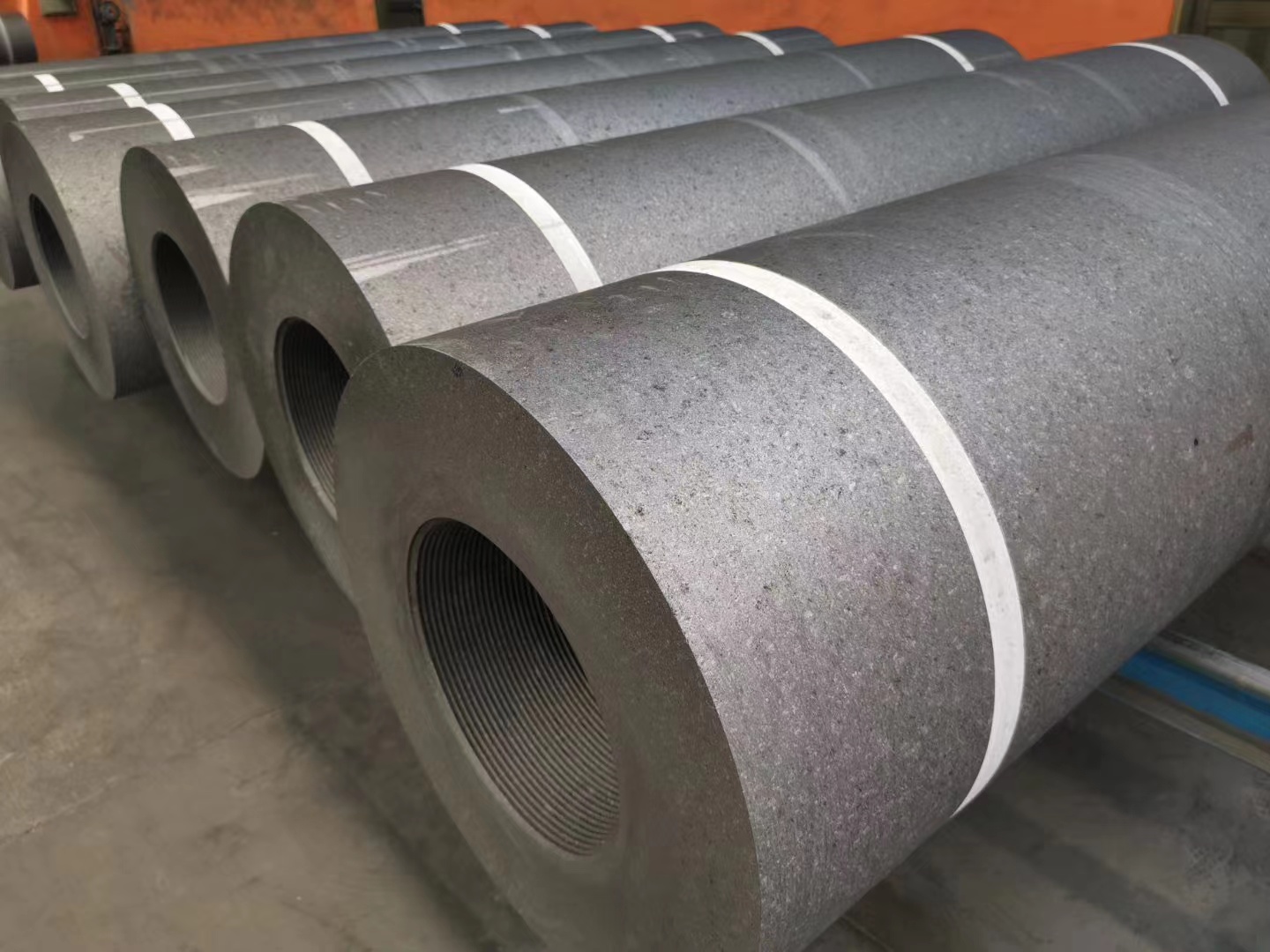

Harga elektroda grafit UHP menjadi perhatian bagi banyak industri dan produksi baja tanur busur listrik dan industri lainnya. Karena mereka adalah bahan baku konduktif utama yang digunakan dalam proses suhu tinggi seperti produksi baja tanur busur listrik. Harga elektroda grafit uhp saat ini adalah antara US$2.200 dan US$2.500 per ton. Pabrik baja memperhatikan harga elektroda untuk memastikan bahwa biaya terkendali selama proses produksi, meningkatkan efisiensi produksi dan mempertahankan tingkat keuntungan yang baik.

Daftar Isi

Beralih

Faktor-faktor yang mempengaruhi Harga Elektroda Grafit UHP

Biaya bahan baku: Elektroda grafit terutama terbuat dari kokas minyak bumi dan kokas jarum. Fluktuasi harga bahan baku ini akan memengaruhi biaya produksi elektroda grafit secara keseluruhan.

Penawaran dan Permintaan: Keseimbangan penawaran dan permintaan pasar dapat memengaruhi harga secara signifikan. Jika permintaan melebihi pasokan atau rantai pasokan terganggu, harga dapat naik.

Biaya energi: The produksi elektroda grafit melibatkan proses suhu tinggi, dan proses pemanggangan serta grafitisasi memerlukan listrik dalam jumlah besar. Perubahan harga energi dapat memengaruhi biaya produksi secara keseluruhan.

Kualitas dan spesifikasi: Kandungan kokas jarum berbeda-beda, mulai dari 30% hingga 100%, dan harga elektroda grafit pun berbeda-beda. Pelanggan biasanya membayar mahal untuk elektroda yang memenuhi standar kualitas yang ketat.

Kondisi Pasar: Kondisi ekonomi secara keseluruhan dan dinamika pasar dapat memengaruhi harga. Faktor-faktor seperti pertumbuhan ekonomi, aktivitas industri, dan ketegangan perdagangan global dapat memengaruhi pasar elektroda grafit.

Tren harga elektroda grafit UHP

Menurut Fastmarketsharga elektroda grafit high power (HP) dan ultra high power (UHP) di China sudah berada pada level yang tinggi pada awal tahun 2022 dan diperkirakan akan terus meningkat, dengan harga fob China untuk elektroda grafit UHP meningkat dari $3.460 menjadi $4.250 menjadi $4.560 per ton. Itu merupakan kenaikan sebesar 19,05%.

Pada saat yang sama, permintaan meningkat, dan ukuran pasar elektroda grafit global diperkirakan mencapai $5,21 miliar pada tahun 2022 dan diperkirakan mencapai $8,91 miliar pada tahun 2032. Tren pertumbuhan ini mencerminkan peningkatan permintaan elektroda grafit, terutama di kawasan Asia Pasifik.

Mengapa mahal?

Performa pemrosesannya luar biasa

- Elektroda grafit lebih mudah diproses dan lebih cepat daripada bahan lainnya (seperti tembaga). Mengurangi biaya produksi. Selain itu, grafit tidak mudah berubah bentuk selama pemrosesan, yang membantu memastikan keakuratan dimensi elektroda.

Resistensi rendah:

- Resistansi rendah dari elektroda grafit berarti bahwa elektroda ini memiliki konduktivitas listrik yang sangat baik. Hal ini memungkinkan elektroda grafit menghantarkan arus secara efisien dalam busur listrik tungkusehingga meningkatkan efisiensi proses pembuatan baja.

Mengurangi kehilangan energi:

- Resistansi rendah membantu mengurangi kehilangan energi karena arus mengalami lebih sedikit hambatan saat melewati material, yang membantu mengurangi biaya pengoperasian dan meningkatkan efisiensi energi. Dalam aplikasi yang memerlukan pemanasan cepat, seperti EDM, elektroda grafit resistansi rendah dapat mencapai suhu yang diperlukan lebih cepat, sehingga meningkatkan kecepatan dan efisiensi pemrosesan.

Kepadatan tinggi:

- Elektroda grafit dengan kepadatan tinggi memiliki kekuatan dan kekakuan mekanis yang lebih baik, yang memungkinkannya menahan tekanan dan gaya benturan yang lebih tinggi, cocok untuk aplikasi yang perlu menahan beban berat. Kepadatan yang tinggi juga berarti bahwa elektroda grafit memiliki ketahanan aus yang lebih baik, yang membantu memperpanjang masa pakai elektroda dan mengurangi keausan selama penggunaan dalam waktu lama. Elektroda grafit dengan kepadatan tinggi menunjukkan stabilitas termal yang lebih baik pada suhu tinggi, yang memungkinkannya mempertahankan bentuk dan kinerjanya di lingkungan pemrosesan suhu tinggi dan tidak rentan terhadap deformasi.

Koefisien ekspansi termal yang rendah:

- Koefisien ekspansi termal elektroda grafit yang rendah, berarti ukurannya tidak banyak berubah apabila suhu berubah. Hal ini penting untuk aplikasi yang memerlukan kontrol dimensi yang tepat, seperti pembuatan cetakan presisi. Selama pemesinan suhu tinggi, koefisien muai panas yang rendah membantu mengurangi keretakan dan deformasi akibat tekanan panas, sehingga meningkatkan kualitas dan keandalan benda kerja Dalam operasi suhu tinggi jangka panjang, elektroda grafit dengan koefisien muai panas yang rendah dapat mempertahankan kinerjanya, mengurangi kebutuhan perawatan dan penggantian yang disebabkan oleh muai panas

Kisaran harga elektroda grafit UHP

Menurut spesifikasi yang berbeda (terutama daya, diameter dan panjang) elektroda grafit, harganya akan bervariasi.

Daya ultra-tinggi (UPH) elektroda grafit

Diameter 300mm-600mm

Kisaran harga: USD 21,00 hingga USD 25,00 per ton

Kisaran harga spesifik untuk spesifikasi yang berbeda

- Diameter 300mm-450mm

Daya sangat tinggi: 2000 hingga 2100 USD per ton

- Diameter 500mm-600mm

Daya sangat tinggi: 2200 hingga 2500 USD per ton

Jika diameter lebih besar dari 600mm: seperti 750mm 、 800mm

Daya sangat tinggi: 2600 hingga 3000 USD per ton

Harga mungkin lebih tinggi, tergantung pada aplikasi tertentu dan kebutuhan pelanggan.

Kesimpulan:

Harga elektroda grafit UHP dipengaruhi oleh bahan baku dan faktor pasar pasokan. Mereka sangat penting untuk tungku busur bertonase besar pembuatan baja karena sifatnya yang unik. Penggunaan elektroda grafit dalam konteks ini sangat penting, karena elektroda ini, yang dibuat dengan bahan berkualitas tinggi dan teknologi canggih, menawarkan konduktivitas listrik yang sangat baik, kekuatan, dan ketahanan terhadap suhu. Atribut-atribut ini memastikan pengoperasian tungku busur listrik yang efisien dan pemurnian baja yang cepat. Konduktivitas listrik yang tinggi dan stabilitas termal elektroda UPH sangat penting untuk mempertahankan kinerja yang stabil dalam metalurgi suhu tinggi, meningkatkan efisiensi dan kualitas pembuatan baja EAF. Hasilnya, elektroda grafit UPH merupakan faktor kunci dalam memastikan produksi baja yang efisien dan mengurangi biaya operasional jangka panjang.

steelmaking-1024x795.jpg)