흑연 전극은 전기 아크로(EAF) 작동에 매우 중요합니다. 흑연 전극은 내부의 원료를 가열하고 녹이는 데 필요한 고전압 전류를 전도하여 제련 또는 정제 작업에 사용할 수 있습니다.

목차

토글따라서 흑연 전극 는 전기로에서 철, 강철 및 기타 금속을 생산하는 데 필수적인 요소입니다. 흑연 전극에 전기가 통하면 전극 사이에 전기 아크가 생성되어 용광로 쉘을 가열하고 전기 아크 용광로 안에 있는 금속 또는 합금을 녹입니다.

전기 아크로에서 흑연 전극이 강철을 녹이는 공정

EAF를 사용하여 강철을 녹일 때 공정은 고철 조각을 용광로에 넣는 것으로 시작됩니다.

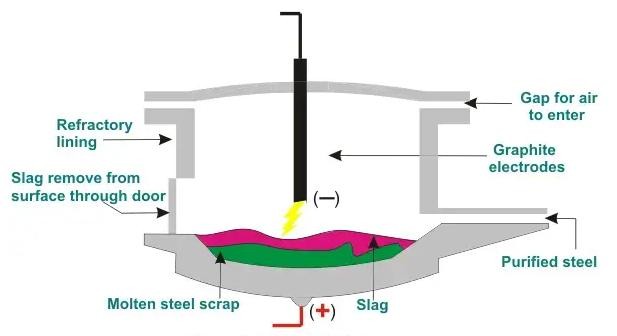

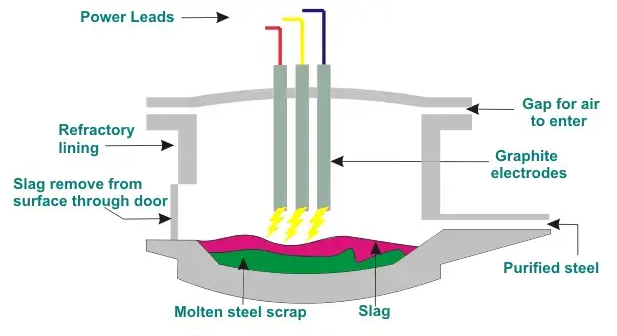

그런 다음 작업자는 흑연 전극을 교류(AC) 또는 직류(DC) 전원을 공급하는 외부 전원에 연결합니다.

그런 다음 작업자는 전원을 켜고 전극의 흑연 끝과 고철 사이에 아크가 형성될 때까지 전류를 조정하여 금속을 용융 액체로 녹이는 강렬한 열을 발생시킵니다.

작업자는 전극을 통해 150,000암페어의 전기를 통과시킵니다. 전극과 전극 사이에 전기 아크를 만들어 흑연 전극 그리고 용광로에서 원료를 가열하여 열을 발생시킵니다.

전기 아크 퍼니스와 그 종류는 무엇인가요?

전기 아크로(EAF)는 흑연 전극을 사용하여 고철을 가열하고 녹여 고품질의 강철을 생산하는 특수 용광로입니다.

전류 특성에 따라 전기 아크 용광로를 AC 전기 아크 용광로와 DC 전기 아크 용광로로 나눕니다. Heroult 가 전기의 발명 이후 1988년에 발명했습니다.

전기 아크로의 등장으로 석탄 기반 제철을 위한 대체 에너지원이 개발되었습니다. 전기 아크로 제강을 통해 고철을 경제적으로 재활용할 수 있게 되었습니다. 궁극적으로 철강을 세계에서 가장 재활용이 잘 되는 재료로 만들었습니다.

흑연 전극을 사용한 전기 아크 퍼니스 작업

아크 퍼니스 전극은 외부 전원에서 전기 에너지를 전기 아크 퍼니스 내부로 전도하여 강렬한 열을 발생시킵니다. 일반적으로 교류 또는 직류 전기는 흑연 전극과 스크랩 재료 사이에 전기 아크를 생성합니다.

온도가 섭씨 5000도에 도달하면 고온이 고철을 녹여 액체 상태로 만듭니다.

그런 다음 제강공이 용광로에서 쇳물을 쏟아냅니다. 일반적으로 각 용광로에는 전극이 3개씩 3개 열로 배열된 9개의 전극이 사용됩니다. 작업자는 흑연 전극을 사용하기 위해 전류와 전압을 조정해야 합니다. AC 전기 아크 퍼니스.

또한 제철소 작업자는 냉각 시스템 및 차폐막과 같은 특정 구성 요소를 사용해야 합니다.

용강이 너무 뜨거워지거나 공정 중에 오염되지 않도록 주의하세요. 이렇게 하면 용광로에서 성공적인 출력을 보장하는 데 도움이 됩니다.

전기 아크로에서 흑연 전극의 중요성

흑연 전극은 저항이 낮고 전류를 전달하는 데 탁월한 전도체입니다. 니들 코크스와 흑연화 정도가 좋은 전극이 더 나은 성능을 발휘합니다.

또한 열팽창 계수가 낮아 전류 경사도가 변해도 변형되지 않습니다.

또 다른 중요한 점은 기계적 강도가 높고 구부러지거나 부러지지 않는다는 점입니다. 이러한 특성을 고려할 때 전기 아크로의 고온 애플리케이션에 매우 적합합니다.

다른 재료로 대체할 수 없기 때문에 흑연 전극은 산업 생산에 필수적입니다.

전기 아크로 제강의 다양한 요구 사항에 따라 세 가지 유형이 있습니다. RP, HP 그리고 UHP 흑연 전극을 사용합니다.

흑연 전극은 아크 퍼니스와 함께 작동합니다.

전기 아크로(EAF)는 흑연 전극을 사용하여 전기 아크를 생성하여 고철을 녹이는 용광로의 일종입니다. EAF는 내화 재료로 채워진 원통형 강철 쉘로 구성됩니다.

용광로 바닥은 용융 금속을 쏟아내기 위해 기울일 수 있는 틸팅 플랫폼으로 구성되어 있습니다. 작업자 삽입 흑연 전극 를 상단의 구멍을 통해 용광로에 넣고 전원에 연결합니다.

작업자가 전원을 켜면 전기 아크가 발생하여 고철을 가열하고 녹입니다. 작업자는 용광로에서 녹은 금속을 부어 원하는 모양으로 주조합니다.

이 공정은 전극을 소모하며 작업자는 주기적으로 전극을 교체해야 합니다. EAF는 일반적으로 고철을 재활용하는 데 사용되며 특수강 생산에도 사용됩니다.

결론

흑연 전극 는 전류가 통과할 때 아크를 생성하기 위해 DC 또는 AC 전기 아크로(eaf)에 사용됩니다. 전기 에너지를 열로 변환하여 고철이나 금속을 제련합니다.

다음을 찾고 계신다면 전기 아크 용광로용 흑연 전극지금 바로 문의해 주시면 도와드리겠습니다. 전문가를 선택하세요 흑연 전극 제조업체 를 통해 EAF 제강 프로세스에 도움을 드릴 수 있습니다.

추가 리소스: