Pasar elektroda grafit diperkirakan akan terus tumbuh dengan mantap, didorong oleh peningkatan produksi baja. Elektroda grafit merupakan bagian tak terpisahkan dari industri pembuatan baja. Dalam proses pembuatan baja, mereka bertindak sebagai penyalur arus listrik ke tungku busur, yang memungkinkan peleburan besi tua dengan suhu tinggi dan efisien. Meskipun pembuatan baja adalah konsumen utama mereka, industri lain, seperti aluminium, silikon, dan produksi panel suryajuga membutuhkannya. Beberapa faktor penting telah memengaruhi perkembangan pasar elektroda grafit, seperti peningkatan kapasitas produksi baja, meningkatnya permintaan tungku busur listrik, dan persaingan yang semakin ketat di pasar.

Daftar Isi

Beralih

Ikhtisar pasar elektroda grafit global

Distribusi pasar elektroda grafit global dan pola regional utama

Pasar elektroda grafit global tidak terdistribusi secara merata, terutama terkonsentrasi di Asia, Eropa, dan Amerika Utara. Asia, yang diwakili oleh Tiongkok, Jepang, dan India, merupakan wilayah produksi dan konsumsi elektroda grafit terbesar di dunia. Memanfaatkan permintaan yang sangat besar dari industri baja. Dengan teknologi industri dan basis manufakturnya yang canggih, Eropa menempati posisi penting di pasar elektroda grafit kelas atas. Terutama dalam pengembangan dan produksi elektroda grafit khusus. Amerika Utara memiliki pengaruh tertentu pada inovasi teknologi elektroda grafit dan standar kualitas. Dan permintaan pasar stabil dan persyaratan kualitas produk tinggi.

Berbagai jenis dan karakteristik aplikasi elektroda grafit

Dari sudut pandang jenis, elektroda grafit terutama mencakup elektroda grafit daya biasa, elektroda grafit daya tinggi, dan elektroda grafit daya sangat tinggi. Elektroda grafit daya biasa cocok untuk tungku busur listrik kecil. Proses produksinya relatif sederhana, berbiaya rendah, terutama digunakan dalam peleburan besi dan baja biasa. Elektroda grafit daya tinggi dapat menahan kepadatan arus yang tinggi. Dan Anda dapat menggunakannya secara luas dalam pembuatan baja tungku busur listrik menengah. Ini dapat meningkatkan efisiensi produksi dan kualitas baja. Elektroda grafit daya ultra-tinggi dirancang untuk tungku busur listrik berdaya sangat tinggi. Dengan konduktivitas yang lebih baik dan ketahanan sengatan panas, untuk memenuhi kebutuhan proses pembuatan baja yang efisien dan modern. Tetapi teknologi produksinya sulit, harganya relatif mahal.

Analisis ukuran pasar elektroda grafit

Tinjauan perkembangan sejarah

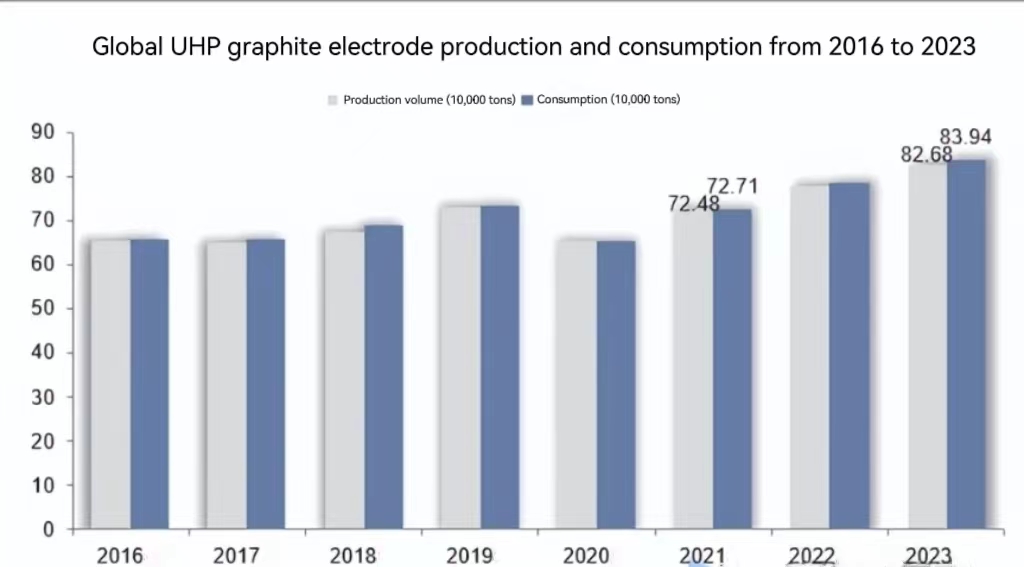

Melihat kembali sejarah, ukuran pasar elektroda grafit telah berfluktuasi seiring dengan naik turunnya industri baja global. Pada awalnya, dengan berkembangnya industri baja tradisional, pasar elektroda grafit tumbuh dengan mantap. Dan teknologinya terus meningkat untuk memenuhi permintaan produksi baja yang terus meningkat. Namun, pada periode krisis ekonomi, penurunan industri baja telah menyebabkan penurunan tajam dalam permintaan elektroda grafit. Dan perusahaan menghadapi kelebihan kapasitas dan penurunan harga.

Analisis situasi saat ini

Saat ini, dengan pemulihan ekonomi global dan transformasi serta peningkatan industri baja, situasi pasar elektroda grafit telah membaik. Didorong oleh kebijakan perlindungan lingkungan, proporsi pembuatan baja tungku busur listrik secara bertahap meningkat. Hal ini mendorong pertumbuhan permintaan pasar elektroda grafit. Khususnya di negara berkembang, perkembangan konstruksi infrastruktur dan industri manufaktur telah mendorong konsumsi baja. Pada gilirannya, hal ini mendorong perluasan pasar elektroda grafit.

Perkiraan masa depan

Ke depannya, diharapkan pasar elektroda grafit akan terus tumbuh. Tetapi tingkat pertumbuhan dapat berfluktuasi karena berbagai faktor. Di satu sisi, industrialisasi di negara berkembang akan terus menciptakan permintaan. Di sisi lain, kemajuan teknologi dapat meningkatkan efisiensi produksi elektroda grafit. Dengan demikian menyeimbangkan penawaran dan permintaan pasar sampai batas tertentu. Dan ukuran pasar diperkirakan akan mencapai tingkat yang lebih tinggi dalam beberapa tahun ke depan.

Studi pangsa pasar elektroda grafit

Klasifikasi produsen elektroda grafit di dunia

Produsen elektroda grafit global dapat dibagi ke dalam tiga kategori. Pertama adalah perusahaan multinasional internasional yang besar, dengan teknologi canggih dan merek yang kuat, seperti GrafTech di Amerika Serikat. Yang kedua adalah keunggulan regional perusahaan, daya saing yang kuat di wilayah lokal atau spesifik, seperti beberapa perusahaan Eropa. Ketiga, perusahaan baru di negara berkembang dengan biaya rendah dan pertumbuhan yang cepat. Diwakili oleh beberapa perusahaan Cina, secara bertahap muncul melalui perluasan skala dan pengejaran teknologi.

Pangsa pasar dan keunggulan kompetitif dari produsen utama

Raksasa internasional seperti GrafTech memimpin pasar elektroda grafit kelas atas. Dan mendominasi pasar elektroda daya ultra-tinggi dengan teknologi canggih, produk kelas atas, dan jaringan penjualan global. Perusahaan Cina lainnya di pangsa pasar domestik cukup besar, mengandalkan keunggulan biaya dan produksi skala besar, dalam produk kelas bawah, daya saing yang kuat. Dan terus berinvestasi dalam penelitian dan pengembangan, meningkatkan kualitas produk, untuk menembus pasar kelas atas.

Tren perubahan dinamis dari pangsa pasar dan alasannya

Dalam beberapa tahun terakhir, pangsa pasar telah berubah secara signifikan. Munculnya perusahaan di negara berkembang telah mengintensifkan persaingan di pasar kelas menengah dan kelas bawah. Dan pangsa pasar mereka secara bertahap meningkat berdasarkan biaya dan keunggulan pasar lokal. Pasar kelas atas, meskipun masih dikuasai oleh raksasa internasional, tetapi dengan difusi teknologi, kesenjangannya semakin menyempit. Selain itu, faktor-faktor seperti pasokan bahan baku, inovasi teknologi, perubahan permintaan industri hilir. Dan kebijakan perdagangan terus mendorong penyesuaian dinamis dalam pangsa pasar.

Tren harga dan Analisis

Komponen harga pasar elektroda grafit

Harga elektroda grafit ditentukan oleh bahan baku, biaya produksi, biaya transportasi, dan hubungan penawaran dan permintaan pasar. Fluktuasi harga bahan baku seperti kokas jarum dan kokas minyak bumi memiliki dampak yang signifikan. Biaya proses, energi dan tenaga kerja pada tahap produksi juga sangat penting. Jarak dan moda transportasi mempengaruhi biaya transportasi. Dalam hal penawaran dan permintaan pasar, harga naik ketika permintaan kuat dan pasokan tidak mencukupi. Dan sebaliknya, berbagai elemen berinteraksi dan bersama-sama membentuk harga pasar elektroda grafit.

Perbandingan perbedaan harga antara pasar domestik dan internasional

Elektroda grafit domestik dalam produk kelas bawah dengan harga lebih rendah dari pasar internasional. Karena sumber daya bahan bakunya yang relatif kaya, biaya tenaga kerja yang rendah, dengan keunggulan biaya. Dalam persaingan internasional dengan keunggulan harga untuk menempati pangsa tertentu. Di bidang elektroda grafit kelas atas, merek internasional mengandalkan teknologi canggih, kualitas tinggi, dan nilai merek. Harganya lebih tinggi dari domestik. Namun dengan peningkatan teknologi dalam negeri, kesenjangan harga produk kelas atas berangsur-angsur menyempit. Dan persaingan pasar menjadi lebih ketat.

Karakteristik harga berbagai jenis elektroda grafit

Harga elektroda grafit daya biasa relatif stabil. Didominasi oleh faktor dasar bahan baku dan penawaran dan permintaan, fluktuasinya kecil. Harga elektroda grafit daya tinggi sering berfluktuasi. Hal ini sangat dipengaruhi oleh peningkatan proses dan perubahan permintaan di industri baja hilir. Elektroda grafit shp karena teknologi yang kompleks, kesulitan produksi yang tinggi, harga tinggi dan fluktuasi yang tajam, dan permintaan manufaktur kelas atas sangat terkait erat. Perubahan kecil dalam penawaran dan permintaan pasar dapat menyebabkan fluktuasi harga yang signifikan.

Analisis segmen pasar

Keunikan pasar batang elektroda grafit

Pasar batang elektroda grafit terkait erat dengan pengembangan tanur busur listrik di industri baja. Dan itu unik karena sangat sensitif terhadap kapasitas dan tingkat operasi tungku busur listrik. Dengan perkembangan tungku busur listrik ke skala besar dan efisiensi tinggi, kualitas, kinerja, dan spesifikasi batang elektroda semakin ketat. Persaingan pasar sangat ketat, fenomena homogenitas produk menonjol. Perusahaan perlu melakukan upaya pengendalian biaya, inovasi teknologi, dan peningkatan kualitas. Sambil berfokus pada pembangunan merek dan akumulasi sumber daya pelanggan, untuk memenangkan keunggulan kompetitif.

Segmen pasar

Pasar elektroda grafit kaliber besar

Pasar elektroda grafit kaliber besar memiliki potensi pertumbuhan yang besar. Berkat maraknya tungku busur listrik berskala besar di industri baja. Namun, ambang batas teknologi produksinya tinggi. Dan kualitas bahan baku menuntut, dan pasokan pasar saat ini terkonsentrasi di beberapa perusahaan dengan kekuatan teknis yang kuat. Perusahaan-perusahaan ini dengan keunggulan teknis dan efek skala, menempati ruang keuntungan yang lebih tinggi. Tetapi juga menghadapi risiko pasokan bahan baku yang tidak stabil, penelitian teknologi dan investasi pengembangan. Dan lebih sedikit pendatang baru di pasar, lanskap persaingan relatif stabil.

pasar elektroda grafit shp

Elektroda grafit Shp berada di kelas atas industri, dengan konten teknis dan nilai tambah yang tinggi. Pasar global terutama dimonopoli oleh beberapa perusahaan terkenal secara internasional, seperti beberapa perusahaan di Amerika Serikat dan Jerman. Mereka mendominasi pasar global berdasarkan keunggulan teknis jangka panjang yang terakumulasi, sistem layanan penjualan yang sempurna, dan pengaruh merek. Dalam beberapa tahun terakhir, meskipun perusahaan-perusahaan Cina telah membuat terobosan teknologi, masih ada kesenjangan dalam stabilitas teknis dan pengenalan merek. Dan mereka berusaha mengejar dan mematahkan pola monopoli internasional.

Pasar elektroda grafit RP

Pasar elektroda grafit RP kecil tetapi ditargetkan, dengan fokus pada bidang peleburan baja khusus kelas atas dan peleburan logam non-besi, dengan nilai tambah produk yang tinggi. Proses produksinya rumit, persyaratan bahan baku dan teknologi pemrosesan sangat tinggi. Dan pasar global dikendalikan oleh beberapa perusahaan terampil. Perusahaan-perusahaan ini mengandalkan proses teknis yang unik dan kualitas produk yang stabil untuk memenuhi kebutuhan pelanggan kelas atas. Dengan hambatan yang tinggi untuk memasuki pasar. Dan persaingan terutama berkisar pada inovasi teknologi dan kualitas produk.

Kesimpulan

Pasar elektroda grafit dipengaruhi oleh berbagai faktor. Termasuk regionalisasi, fluktuasi, perubahan saham, harga yang kompleks, dan karakteristik segmentasi pasar. Perusahaan harus berinovasi dan beradaptasi, dan pemerintah serta asosiasi harus memandu industri ini menuju pembangunan hijau dan berkelanjutan. Untuk meningkatkan daya saing global.

Sumber Daya Lainnya:

Elektroda Grafit dan Jarum Kokas.

Baja - Peleburan, Paduan, Pemurnian.