Introduction

Comment l'acier est-il testé ? Explorons-le ! Moules en graphite pour la coulée Aide. Ces métaux chauds comme l'or et l'acier sont façonnés dans ces moules. Les moules sont résistants jusqu'à 3000°C. Les pièces en acier testées vous permettent de réaliser différentes choses. Vous voulez en savoir plus ? Lisez la suite !

Table des matières

Toggle

Comprendre le rôle des moules en graphite dans la coulée !

Les moules en graphite pour la coulée permettent de façonner les métaux chauds tels que l'or, l'argent et le cuivre. Ces métaux sont utilisés pour fabriquer des objets tels que des barres ou des pièces de monnaie. Les le moule en graphite peut résister à des températures allant jusqu'à 3000°C. Il n'y a pas de danger à le faire fondre. Les moules en graphite contiennent moins de 0,1% de cendres et gardent les métaux propres.

Ils ne se plient pas et ne se cassent pas facilement. Vous pouvez littéralement y verser du métal, le laisser refroidir et le faire ressortir ! Ils sont solides, durent longtemps et constituent d'excellents moules pour de nombreuses utilisations. De plus, les moules en métal sont moins coûteux.

Types de moules en graphite en fonction des applications de coulée !

- Moules permanents

Lorsque vous fabriquez des formes métalliques, vous utilisez des moules permanents. Les moules peuvent durer longtemps. Ces moules sont solides. Il est possible de fabriquer des pièces pesant jusqu'à 150 kg. Les moules refroidissent rapidement le métal.

La forme solide est poussée par des goupilles. Elles constituent des pièces du moteur, des pistons, des engrenages, etc. Le refroidissement est rapide. Les moules permanents peuvent être utilisés plusieurs fois.

- Moules perdus

Les fabricants de pièces qui utilisent cette méthode ne fabriquent les pièces qu'une seule fois. Le moule est ensuite cassé. La forme est donnée par du sable ou de la cire. Les moules sont également utilisés pour les métaux tels que l'acier et le bronze. Le moule disparaît après utilisation. Vous pouvez fabriquer des formes minuscules et détaillées telles que des lames. Les moules en graphite pour le moulage permettent de fabriquer des pièces complexes. A l'intérieur, ils sont fondus et se détachent dans des moules.

- Moules de coulée sous pression

Dans le cas du moulage sous pression, le métal en fusion est mis en forme par la pression d'un moule. Les pressions varient de 10 à 300 MPa. On fabrique des blocs moteurs pour les voitures. Le moule se remplit rapidement de métal. Ces moules sont réutilisés.

Les moules en graphite pour la coulée sont destinés aux métaux non ferreux comme l'aluminium. Cela permet de gagner du temps car ils refroidissent rapidement. Les électrodes en graphite de Jinsun Carbon rendre le moulage sous pression plus efficace en accélérant le refroidissement.

- Moules d'investissement

Vous remplissez une coquille en céramique de cire, puis vous la trempez dans la cire. Cette coquille devient le moule. Il peut prendre en charge des métaux comme l'acier. Le moule n'est utilisé qu'une seule fois. Le moule se brise après la coulée. La bonne nouvelle, c'est qu'il est possible de fabriquer des objets si petits et si détaillés que l'on peut produire des pièces minuscules et précises comme des pales de turbine. Le moule refroidit et le métal le remplit.

- Moules pour le moulage au sable

Un moule est créé en remplissant du sable autour d'une forme. Le moule ne fonctionne qu'une seule fois. Il aide les acteurs à jouer de grands rôles comme des tuyaux. Les moules en sable peuvent contenir jusqu'à 7 000 kg de pièces métalliques. Une fois refroidi, le moule est cassé. L'aluminium ou le fer conviennent également. Le sable permet d'obtenir des surfaces rugueuses. Nous créons de grandes pièces métalliques par le biais du moulage en sable en utilisant en partie nos produits en graphite.

| Type de moule | Matériau | Processus de coulée | Plage de température (°C) | Durabilité | Réutilisation |

| Moules permanents | Graphite, Métal | Coulée par gravité | 700 – 1100 | Haut | Multiple |

| Moules perdus | Graphite, Céramique | Coulée à usage unique | 900 – 1400 | Faible | Usage unique |

| Moules de coulée sous pression | Graphite, acier | Coulée à haute pression | 200 – 900 | Très élevé | Multiple |

| Moules d'investissement | Graphite, enduit de cire | Cire perdue | 900 – 1200 | Modéré | Usage unique |

| Moules pour le moulage au sable | Graphite, Sable | Moulage au sable | 900 – 1600 | Faible | Usage unique |

| Moules d'injection | Graphite, Aluminium | Moulage par injection | 300 – 800 | Très élevé | Multiple |

Tableau sur les types de moules en graphite en fonction des applications de coulée !

Propriétés clés du graphite pour la fabrication de moules !

- Conductivité thermique

Il aide les choses à se refroidir très rapidement. Ces chiffres correspondent à une perte de chaleur relativement rapide et peuvent être compris entre 80 et 140. W/m-K. Cela facilite la coulée. Les métaux doivent refroidir et les moules en graphite pour la coulée y contribuent. Le moule offre un moyen supplémentaire de faire passer la chaleur à travers le moule, ce qui permet d'obtenir un métal solide plus rapidement. Lorsque les choses deviennent très chaudes, la chaleur ralentit.

- Point de fusion élevé

Jusqu'à 4000°C, le graphite ne fait pas fondre les métaux car l'or devient très chaud, il reste solide. C'est un excellent moyen de le couler. Les moules en graphite permettent de former le métal sans le chauffer. Par exemple, il est solide même à 1500°C.

- Usinabilité

Vous pouvez couper le graphite facilement. Il est souple et se moule facilement. Vous pouvez le rectifier, le couper ou le polir. Comme les formes sont exactes, on peut fabriquer des objets très petits, par exemple ±0,01 mm. C'est important pour les objets spéciaux, comme les moules à bijoux. Il permet aux moules de durer plus longtemps.

- Résistance à la corrosion

Le plus souvent, le graphite lui-même ne réagit pas avec les métaux. Cela vous permet de garder votre métal coulé propre et pur. Mais l'aluminium et le cuivre, très conducteurs, n'y adhèrent pas.

Il ne rouille pas et ne subit aucune altération pendant longtemps. Les moules en graphite sont très utiles lorsque vous coulez de nombreux métaux différents, car ils sont capables de résister à beaucoup de choses et de revenir en place.

- Résistance aux chocs thermiques

Les fortes variations de chaleur n'affectent pas le graphite. Comme il ne se dilate pas beaucoup (3,5 - 5 × 10^-6°C^-1), il n'a pas tendance à se fissurer. Il reste solide même lorsque le métal chaud touche un moule froid. Il possède une très bonne résistance à la flexion, de sorte que les objets ne se fissurent pas en cas de réchauffement rapide.

Processus de fabrication des moules en graphite !

- Conception CAO

Le moule en graphite est dessiné à l'aide de CAD. Il peut produire des formes exactement comme des carrés ou des cercles. Des chiffres comme 50 mm ou 100 mm permettent d'y insérer du métal. Les métaux chauds, ou les métaux tels que le cuivre qui fond à 704°C, sont placés dans le moule. En vous aidant à fabriquer sans erreur des pièces de monnaie, la CAO vous rend service.

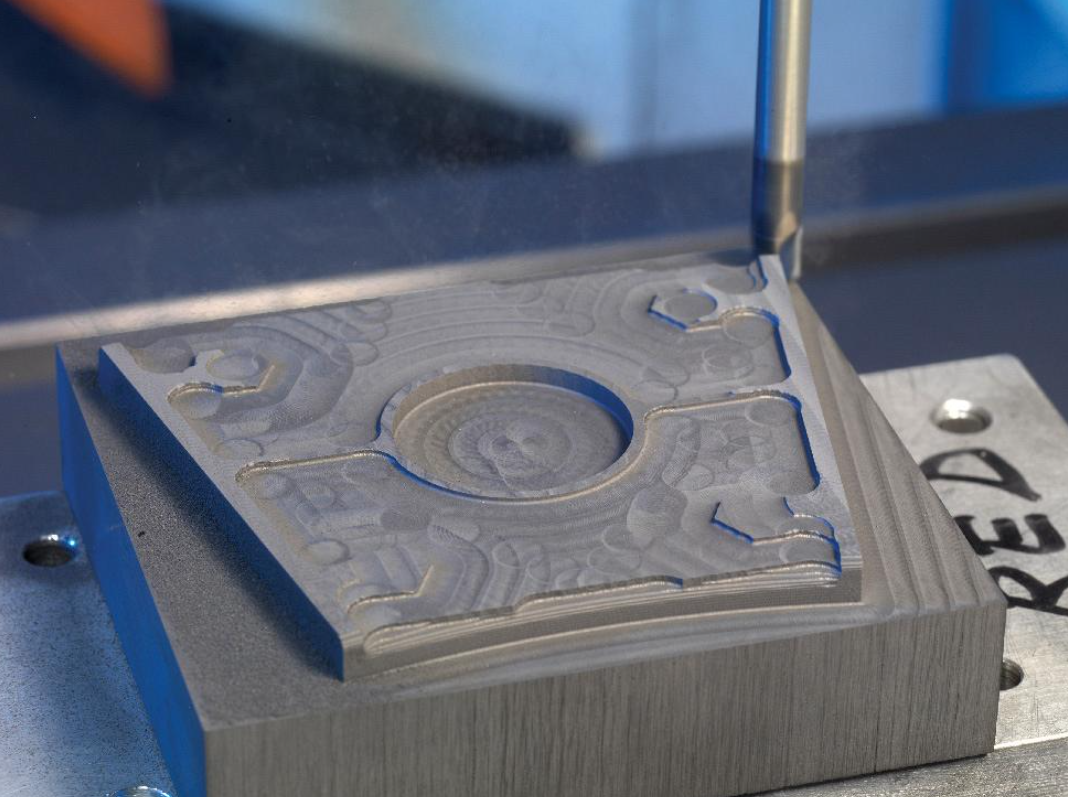

- Usinage CNC

Le moule est découpé à l'aide d'outils tranchants par une machine CNC. Vous lui donnez le dessin. La machine peut réaliser des trous profonds ou des lignes lisses. Elle tourne très vite, environ 500 mm/min. Elle est très précise à ±0,005 pouce près. Pour le moulage des métaux, de l'argent, on obtient des moules parfaits avec des surfaces brillantes.

- Création de l'empreinte du moule

À l'intérieur du moule, vous découpez un espace pour le métal. Cette cavité peut avoir une épaisseur de 10 mm ou plus. Les parois doivent être suffisamment solides pour contenir le métal chaud. Vous vérifiez ensuite la taille pour vous assurer que le métal refroidit rapidement. Cela permet de fabriquer rapidement de belles pièces à partir du moule.

- Inspection de la qualité

Vous vérifiez soigneusement le moule. Ensuite, tu utilises des lasers et des outils similaires pour vérifier que la taille est correcte. La surface ne doit pas être fissurée et doit être lisse. Avant de pouvoir être utilisé pour le moulage de pièces, le moule doit passer tous les tests.

Quels sont les facteurs à prendre en compte lors du choix des moules en graphite ?

- Résistance à la température

Lors de la coulée des moules en graphite, ceux-ci deviennent très chauds. Ils peuvent atteindre une température de 1649°C (3000°F). S'ils ne se cassent pas, ils peuvent le faire. Le point de fusion du cuivre est de 1083°C (1981°F). À cette température, les bons moules sont solides. Le métal doit être plat, ou ils doivent produire de la chaleur de manière uniforme. Optez pour des moules avancés à grain fin présentant une conductivité thermique de 120 W/mK.

- Durabilité

Lorsque les moules en graphite sont utilisés, certains sujets coulés sont soumis à une forte pression. Le moule est résistant si la densité est supérieure à 1,7 g/cm³. Le nickel fond à 1427°C (2600°F), il faut donc des moules dignes de confiance. Les bons moules ont une résistance de 30 MPa. La coulée rapide, sans dommage, est due à la solidité des moules.

- Taille du moule

Les moules doivent correspondre exactement à la taille du métal. Les grands moules jettent des matériaux, les petits se bouchent. Les dimensions de la cavité sont comprises entre 100 et 150 mm. Les moules de la bonne taille permettent d'obtenir de meilleurs résultats de coulée et des produits plus lisses.

- Matériau de fonderie

Moules en graphite pour la coulée fonctionnent bien avec de nombreux métaux comme l'or ou l'aluminium. Le point de fusion de l'or est de 1948°F (1064°C). Le point de fusion de l'aluminium est de 660°C (1220°F). Pour les matériaux plus tendres, moules à grains fins ayant une porosité 30% sont parfaits. Pour éviter de rayer ces métaux, il faut des moules lisses. La meilleure façon de couler le cuivre est d'utiliser des moules à haute conductivité de 120 W/mK.

- Taux de refroidissement

Les moules permettent de définir la vitesse de refroidissement du métal. Des fissures apparaissent lorsque le métal est refroidi trop rapidement. Le métal se casse si la vitesse est supérieure à 5°C par minute. Les métaux refroidis lentement ont des moules d'environ 25 mm d'épaisseur. Les surfaces sont lisses et les moules de bonne qualité avec 120 W/mK. La coulée finale peut également être rendue résistante et solide par le refroidissement, un refroidissement uniforme.

Maintenance et entretien des moules en graphite pour des performances durables !

- Nettoyage de surface

Pour enlever la poussière, nettoyez votre moule avec un chiffon doux. Appliquez un nettoyant après 100 coulées, utilisez un nettoyant spécial. Gardez-le au sec pour éviter la rouille. Une fois la séance terminée, essuyez doucement les évents. N'utilisez jamais rien de fort, cela abîme le graphite. Cela permettra à votre moule de durer plus longtemps. Pour obtenir de bons résultats, nous voulons que la surface reste lisse.

- Réparation des dommages

Toutes les 50 utilisations, vérifiez qu'il n'y a pas de fissures. Et poncez les petites rayures avec des outils doux. Des fissures importantes ? De nouveaux blocs ou inserts sont ajoutés. Le graphite peut s'abîmer sous l'effet de la chaleur, n'essayez donc pas de l'utiliser pour réparer les fissures. Mettez fin au problème rapidement afin qu'il ne s'aggrave pas. Il faut s'occuper des moisissures.

- Environnement de stockage

Conservez-la dans une boîte sèche et stockez votre moule en graphite. Les dommages sont causés par un excès d'humidité. Utilisez des couvercles pour éviter la poussière. Gardez l'espace de stockage au frais. Ne placez pas votre moule à proximité d'acides ou de produits chimiques. Vous éviterez ainsi que la corrosion ne s'installe ou que le moule ne soit endommagé. Lorsque le moule est bien stocké, il dure plus longtemps.

- Procédures de manutention

Manipulez les moules en graphite avec précaution. Utilisez des poignées souples pour les soulever. Ils se rayent s'ils touchent des outils tranchants. Ne déplacez pas le moule lorsqu'il est chaud afin d'éviter de l'endommager. Si le moule est chaud, il peut se fissurer lorsqu'il est déplacé. Le moule doit toujours être transporté avec précaution. La surface reste lisse et fonctionne bien.

- Calendrier d'inspection

Inspectez votre moule après 50 coulées. Vérifiez si les bords sont fissurés ou rouillés. Il est préférable d'ignorer les petites fissures, mais lorsqu'elles s'agrandissent, elles posent de plus gros problèmes. Vérifiez que les évents ne sont pas poussiéreux. Ce programme vous permet de prendre les choses en main plus tôt. Si vous procédez à des vérifications minutieuses, votre moule en graphite gardera sa forme.

Quels sont les problèmes courants liés aux moules en graphite et comment les éviter ?

- Craquage

Si vous chauffez votre moule trop rapidement, vous risquez de le fissurer. Ne l'utilisez qu'une seule fois après l'avoir maintenu à 300-500°C. Le taux de dilatation thermique doit être de 4,5 × 10-⁶ /K pour le graphite. En outre, le moule peut se fissurer sur les arêtes vives. Une conception lisse du moule - sans angles vifs - est indispensable. Trop de contraintes le briseraient.

- L'érosion

Lorsque le métal coule trop vite, on dit qu'il est érodé. Cela ruine les moules. Limitez le débit à moins de 45 m/s. Les moules en graphite destinés à la coulée sont confrontés à l'érosion à partir de 700°C. Pour protéger le graphite, il faut le recouvrir de certains types de nitrure de bore. Vous devrez vérifier le moule tous les 50 cycles de coulée. Il est difficile de vérifier souvent les dommages.

- Contamination

Les métaux sales abîment parfois les moules. Brossez-les délicatement avec du moule ou des produits chimiques. Maintenez un niveau d'impureté inférieur à 0,5% dans votre matériau graphite. Vous devez filtrer le métal en fusion entre 600 et 800 microns. Les bonnes pièces ne sortent pas d'un moule sale. Nettoyez-le souvent pour éviter les mauvaises pièces et gagner du temps.

- Choc thermique

Le moule se casse s'il chauffe ou refroidit trop vite. Préchauffez les moules à 300-500°C. Cela permet d'éviter les fissures. JinSun Carbon réduit les problèmes en utilisant du graphite avec un une conductivité thermique de 140 W/m-K. Le contrôle de la chaleur du moule se fait toujours à l'aide d'un thermomètre. Ne le laissez pas refroidir trop vite !

- Refroidissement inégal

Un refroidissement inégal déforme les moules. Il crée des pièces de mauvaise qualité. Le moule doit être conçu de manière uniforme et aucune de ses parties ne doit être plus fine que 3,5-7,5 L/min. Cela permettra au moule de durer plus longtemps. Bien entendu, si le refroidissement est trop rapide à certains endroits, le moule peut se briser. Pour obtenir les meilleurs résultats, il faut veiller à ce que le refroidissement soit homogène.

Conclusion

Le test de l'acier n'est pas une tâche difficile à réaliser, avec les bons outils. Moules en graphite pour la coulée simplifient le façonnage des métaux. L'avantage est que les moules solides durent et qu'ils fonctionnent à la chaleur. Consultez le site JINSUNCARBON pour les meilleurs produits en graphite qui s'intègrent parfaitement à vos projets de moulage. Facilitez le moulage dès aujourd'hui !