Graphite electrode is a conductor electrode used in electric arc furnaces. The heat generated after power is turned on can be used to steelmaking. In this article, we will introduce graphite electrodes in depth, including its production process, properties and application.

Table of Contents

ToggleDefining Graphite Electrode

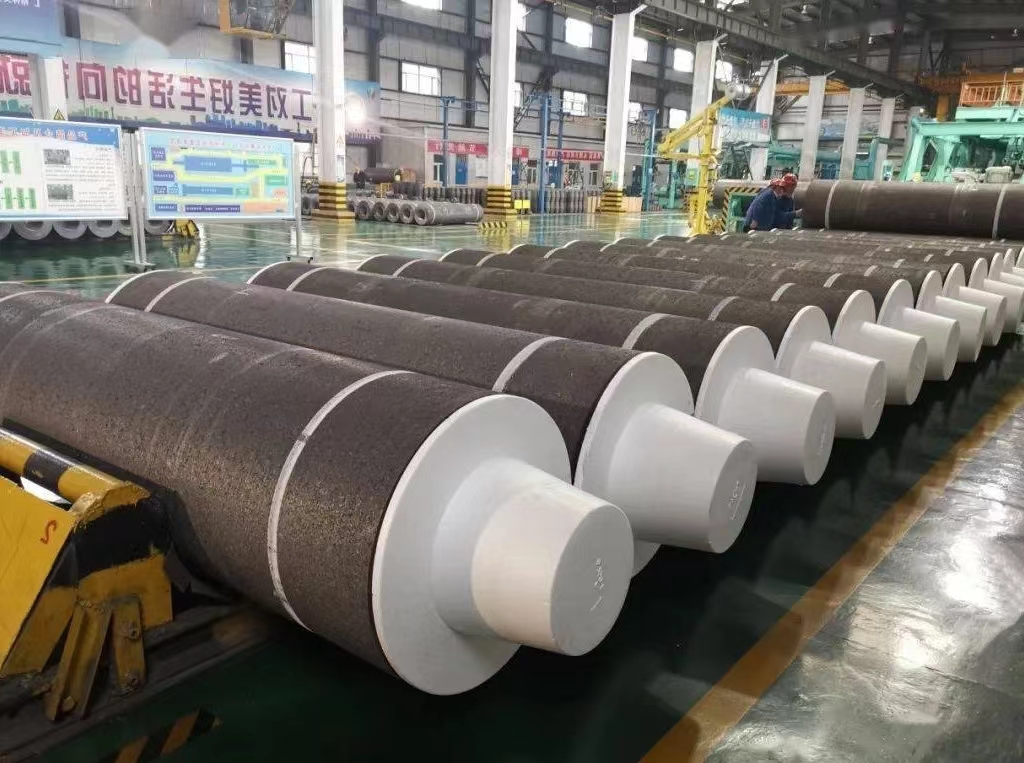

A graphite electrode is an essential conductive components in electric arc furnace (eaf) steelmaking. Crafted from high-quality needle coke (a type of petroleum coke), these electrodes are known for their superior electrical conductivity, thermal resistance, and mechanical strength.

Types of graphite electrode

- Ordinary power graphite electrode (RP), the current density in the use of electric arc furnace should be lower than 17A/cm2. The raw materials are mainly petroleum coke and coal tar pitch, the production cycle is about 45 days. You can use it to smelt ordinary steel, silicon and yellow phosphorus.

- High power graphite electrode (HP), it allows the current density to pass between 18~25A/cm2, the raw materials are petroleum coke, coal tar pitch, and needle coke. The production cycle is about 60 days, mainly used for smelting stainless steel and corundum.

- Ultra-high power graphite electrode (UHP), the current density used in AC electric arc furnace is greater than 25A/cm2. The raw materials include petroleum coke, needle coke, coal tar pitch, and the needle coke content is greater than that of HP grade. However, the production cycle is greater than 65 days, and you can use it for smelting fine steel and special steel.

Production Process

The creation of a graphite electrode undergoes a multi-step, precise process designed to preserve and enhance its desirable properties.

Raw Material Processing

The raw materials including petroleum coke, needle coke and pitch coke as raw materials, all of which are carbon-based substances.

Forming

This mixture is then molded into the desired shape through extrusion. The result is “green stock,” baked at high temperatures to carbonize the pitch and harden the structure.

Baking

Place the blank in a baking furnace and heat it to above 1200 degrees Celsius in a controlled atmosphere to volatilize the binder such as asphalt.

Graphitization

The final crucial step is graphitization. Here, we heated to temperatures above 3000°C, causing the carbon atoms to rearrange into a crystalline graphite structure. This process imparts the electrodes with their unique electrical and thermal properties.

Graphite Electrode Properties

They stand out in their ability to withstand extreme conditions, an attribute that is mainly due to their unique characteristics.

Electrical Conductivity

Being composed of graphite, these electrodes are excellent conductors of electricity, enabling efficient energy transfer in applications that require high currents.

Thermal Resistance

They can endure extremely high temperatures without losing their structural integrity. This property is invaluable in metallurgical processes, which often involve heat-intensive operations.

Mechanical Strength

Under the action of external forces, it generally does not bend or break. This makes it durable and reliable in harsh industrial environments.

Chemical Inertness

They are chemically inert and do not readily react with molten metals or other materials in the furnace. This characteristic ensures the purity and integrity of the final products.

Applications of Graphite Electrodes

It mainly includes various electric furnaces such as electric arc furnace steelmaking furnace, ore heat furnace, resistance furnace, and the production of heterogeneous graphite products.

In electric arc steelmaking, current is introduced into the furnace through graphite electrodes, and the heat generated by the arc is used for smelting. You can use electrodes of different diameters and different powers according to the capacity of the electric furnace. In addition, in the refining furnace, graphite electrodes refine molten steel under conditions such as high temperature and high pressure to improve its purity and quality.

Ore heat electric furnaces are mainly used to produce ferroalloys, pure silicon, yellow phosphorus, matte and calcium carbide. Its characteristic is that the lower part of the conductive electrode is buried in the charge, and the current generates heat through the resistance of the charge.

In terms of resistance furnaces, graphitization furnaces for the production of graphite products, melting furnaces for melting glass, and electric furnaces for the production of silicon carbide are all resistance furnaces. The materials loaded in the furnace are both heating resistors and objects to be heated. Usually, the graphite electrodes for conduction are embedded in the furnace head wall at the end of the furnace bed.

In addition, we can process graphite electrodes into various special-shaped products such as crucibles, graphite boats, hot pressing molds and vacuum furnace heating elements. These products you can use them in many industrial fields, such as glass manufacturing and silicon carbide production.

Conclusion

Due to its excellent conductivity, high temperature resistance and corrosion resistance, graphite electrodes play an indispensable role in many industries such as electric arc furnace steelmaking and are important materials in modern industrial production.