Les fours à arc électrique sont très importants dans la fabrication industrielle de l'acier. Plus de 95% d'acier électrique est produit par des fours à arc électrique. Commençons Dans ce blog, vous découvrirez le fonctionnement d'un four à arc électrique, ses composants et ses avantages, les principaux matériaux utilisés, ainsi que la comparaison entre les fours à arc électrique et les autres types de fours.

Table des matières

ToggleCe qu'il faut faire Qu'est-ce qu'un four à arc électrique (FÉA) ?

Le four à arc électrique (EAF) est un four qui fait fondre le métal dans un arc électrique à haute température, en particulier pour la fonte de l'acier. Le groupe d'électrodes EAF génère un arc électrique qui produit de la chaleur et fait fondre le métal chargé. Par rapport aux hauts fourneaux à charbon, les fours à arc électrique fonctionnant toute l'année sont plus flexibles et plus propres. La production d'acier par four à arc électrique est économe en ressources ; elle minimise les déchets par rapport aux sources d'acier, et l'utilisation de matériaux recyclés Initiale Retour d'expérience.

La ferraille d'acier recyclable est traitée par des fours à arc électrique dans des mini-aciéries. Grâce à la flexibilité des matières premières utilisées, les fours électriques à arc sont idéaux pour la fabrication écologique et économique de l'acier. La coulée en bandes permet d'obtenir une large gamme de compositions et un acier de haute qualité, ce qui la rend adaptée aux aciers spéciaux et aux alliages.

Comment fonctionne un four à arc électrique ?

-

Chargement

La première partie du processus dans votre four à arc électrique est le chargement, c'est-à-dire l'introduction des matières premières dans le four. Les principales matières premières utilisées sont la ferraille, la fonte brute et parfois le fer à réduction directe (DRI). Ces matières sont introduites dans le four par le système de chargement. Les progrès récents des systèmes de chargement permettent d'atteindre des niveaux élevés d'automatisation, ce qui permet d'ajouter des matériaux avec une composition chimique à la fois précise et efficace. Il est possible d'effectuer le chargement par lots en utilisant de grands conteneurs appelés "paniers", qui sont chargés de ferraille puis insérés dans le four simultanément - ou en continu via des convoyeurs.

-

Fusion

Une fois le four chargé, la fusion est l'étape suivante. Dans ce processus, les électrodes (au lieu d'un matériau à base de graphite) sont placées dans le four et une haute tension les traverse. Cela crée un arc électrique qui surchauffe le métal jusqu'à ce qu'il fonde. La température à l'intérieur du four à arc électrique peut atteindre 3 500 °C, ce qui est plus que suffisant pour faire fondre la ferraille et les autres matières premières. Le four électrique utilise l'arc, la chaleur développée entre les électrodes et les charges ; le système de laitier protège la composition chimique du bain de fusion à l'aide d'une couche limpide comme couverture, ce qui permet d'obtenir le débit de fusion le plus élevé.

-

Raffinage

L'étape suivante consiste à affiner le métal une fois qu'il a été fondu. L'affinage est le processus de purification du métal sous sa forme patiente et fondue. Au cours de l'affinage, de l'oxygène est généralement insufflé dans le four à l'aide d'une lance afin d'oxyder et d'éliminer les impuretés telles que le carbone, le phosphore ou le soufre. Ce sont les impuretés denses qui sont mélangées à d'autres fondants tels que la chaux et le spath fluor pour former un laitier qui retient les impuretés incorporées dans le métal. Généralement contrôlée par divers capteurs et systèmes de contrôle avancés, cette fonctionnalité est essentielle pour générer un acier de haute résolution aux propriétés uniques.

-

Taraudage

Le processus de coulée est la dernière étape du processus de fabrication d'un four électrique. Au cours de la troisième étape, l'acier en fusion (contenu dans le four) est acheminé vers les poches de coulée, qui sont les récipients utilisés pour transporter l'acier liquide dans l'aciérie en vue de son traitement, comme la coulée et la mise en forme. Le taraudage est également un processus très subtil qui exige un contrôle, car nous devons tarauder une quantité spécifique d'acier en fusion et réduire l'entraînement du laitier. Les températures de taraudage sont étroitement surveillées à l'aide de ces boutons afin de garantir que la température de l'acier en fusion est à un niveau approprié pour le traitement en aval.

Capacité et types de fours à arc électrique

Four à arc électrique indirect

Un four à arc électrique à courant alternatif (AC EAF) utilise le courant alternatif (AC) qui circule à travers les électrodes en graphite pour produire l'arc électrique utilisé pour la fusion. Les fours à arc électrique à courant alternatif sont le type de four le plus utilisé pour la fusion de l'acier et, grâce à leur flexibilité, ils peuvent servir à de multiples applications. Ces fours sont de conception assez simple et peuvent fondre pratiquement n'importe quel type de ferraille. Les fours à courant alternatif sont un type de four électrique très polyvalent qui peut être allumé et éteint rapidement, ce qui est idéal pour la production d'acier à petite et moyenne échelle.

Four à arc électrique direct (DC EAF)

L'arc électrique est produit en utilisant du courant continu (DC) dans un four à arc électrique DC (DC EAF). Un four à arc électrique à courant continu nécessite moins d'électrodes qu'un four à arc électrique à courant alternatif, ce qui permet de réduire les coûts. En général, il n'y a qu'une seule électrode en graphite dans un four à courant continu, qui reste en place plus longtemps et assure la stabilité de l'arc. En outre, les fours à courant continu ont tendance à être plus silencieux et à offrir un meilleur rendement énergétique. Mais comme leur structure est généralement plus complexe, le coût initial de l'installation peut également être plus élevé.

Four à arc électrique immergé

Le four à arc submergé (SAF) est un type de four spécifique qui est principalement utilisé pour produire des ferro-alliages ou d'autres métaux. Les électrodes sont partiellement immergées dans les matériaux de charge afin de créer une atmosphère réductrice adaptée à certaines réactions métallurgiques, par exemple dans le SAF. Les SAF ne sont pas utilisés pour faire fondre l'acier, comme c'est le cas avec les fours électriques à arc standard, mais plutôt pour traiter des minerais tels que le manganèse ou le chrome afin de produire des composants en alliage. Les fours électriques à arc submergé spécialisés peuvent être conçus pour atteindre des températures de fusion élevées, ce qui facilite la recherche de profils appropriés pour les alliages présentant les propriétés souhaitées.

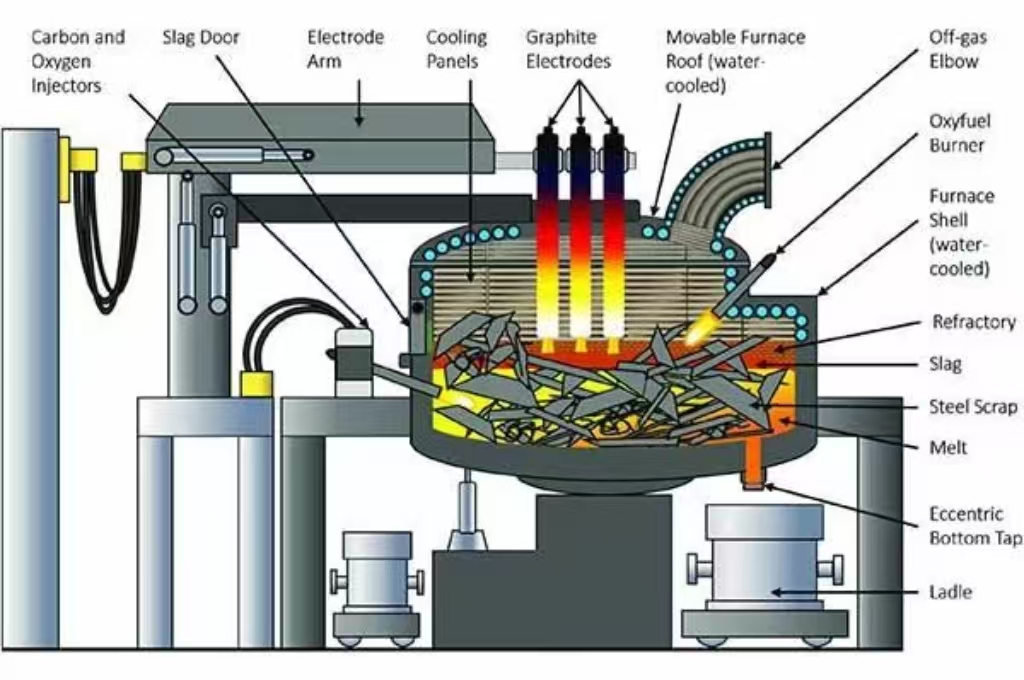

Principaux composants d'un four à arc électrique

Coquille et toit

La coque du four est généralement soudée à partir de plaques d'acier et présente une certaine résistance et une certaine rigidité. La construction est généralement en acier lourd pour résister aux températures élevées qui traversent le four. Le toit est amovible et sert à charger les matières premières dans le four. En outre, les orifices des électrodes, par lesquels les électrodes pénètrent dans le four, se trouvent dans le toit.

Revêtement de four

Matériaux réfractaires Le revêtement des fours contient des matériaux réfractaires très résistants à la chaleur. Il protège l'enveloppe du four, l'empêchant d'être endommagée par le métal en fusion. En outre, le revêtement réfractaire contribue à l'isolation du four, ce qui permet de conserver la chaleur et d'accroître l'efficacité énergétique. Un jour ou l'autre, le revêtement devra être remplacé pour qu'il fonctionne au mieux.

Système de charge

Le système de chargement alimente les matières premières telles que la ferraille d'acier directement dans le four. Dans ce système, des grues et des godets appelés "paniers de chargement" sont généralement utilisés pour charger la ferraille dans le four rapidement et en toute sécurité. Les systèmes de chargement plus récents peuvent être des bandes transporteuses ou d'autres systèmes automatisés qui permettent un chargement continu, ce qui améliore la productivité et l'efficacité.

Transformateur de four à arc électrique

Le transformateur du four à arc électrique convertit et transporte l'énergie nécessaire aux électrodes. Il transforme également l'électricité haute tension du réseau électrique en une tension plus faible adaptée à l'arc électrique. La régulation du courant assurée par le transformateur est importante pour garantir des conditions d'arc stables et contrôler la fusion. Un transformateur bien conçu permet de conserver l'énergie utilisée dans un environnement sûr.

Système de refroidissement

Les températures produites par un four à arc électrique étant exceptionnellement élevées, un système de refroidissement est nécessaire pour éviter la fusion. En général, le refroidissement s'effectue au moyen de panneaux refroidis à l'eau. Ceux-ci absorbent la chaleur excessive et maintiennent les températures du four à des niveaux plus sûrs. Un refroidissement efficace prolonge la durée de vie de l'appareil et empêche la surchauffe des électrodes, du toit et des panneaux latéraux.

Système de dépoussiérage des fours à arc électrique

L'exploitation d'un four électrique à arc produit des poussières. Cette poussière contient des matériaux nocifs tels que des oxydes métalliques et d'autres matériaux. Une partie de cette poussière est capturée par un système de dépoussiérage, où les composants nocifs sont séparés et détruits ou les métaux précieux recyclés. Une gestion efficace des poussières est donc essentielle pour se conformer à la législation environnementale et maintenir un environnement de travail sûr.

Avantages de l'utilisation des fours à arc électrique

Efficacité du recyclage

Les fours électriques EAF sont donc extrêmement importants pour l'économie circulaire, car ils permettent de recycler efficacement la ferraille. L'utilisation de la ferraille réduit la nécessité d'extraire et de raffiner du minerai vierge, ce qui permet de préserver à la fois les ressources naturelles et l'énergie.

Flexibilité

Les fours à arc électrique sont faciles à démarrer ou à arrêter, ce qui convient parfaitement à la production d'acier en petites séries. C'est un réel avantage par rapport aux hauts fourneaux, qui doivent fonctionner en continu.

Réduction des émissions de carbone

En fait, les fours à arc électrique émettent beaucoup moins de carbone que les hauts fourneaux. Ils contribuent à réduire les émissions de gaz à effet de serre, en particulier lorsqu'ils sont alimentés par des énergies renouvelables, car ils utilisent de l'électricité plutôt que du coke.

Principaux matériaux utilisés dans les aciéries électriques

Ferraille d'acier

Les fours à arc électrique sont un type de four sidérurgique qui utilise la ferraille comme matière première principale. Cette ferraille provient de divers endroits, notamment de voitures hors d'usage, de maisons rasées et de déchets d'usine. Le recyclage de la ferraille d'acier est un moyen plus écologique d'utiliser les ressources naturelles de la terre et contribue à réduire les déchets.

Électrodes de four à arc

L'arc électrique qui fait fondre la ferraille d'acier est créé par le passage de l'électricité à travers ces électrodes en graphite. Cependant, en raison du processus de fusion, ces électrodes doivent supporter des températures élevées dans le four à arc électrique et sont progressivement brûlées. Les électrodes doivent être remplacées régulièrement, ce qui ajoute un autre élément de coût à l'utilisation continue du four à arc électrique.

Scories de four à arc électrique

Le laitier est le résultat des impuretés provenant des matières premières. Il s'agit d'un résidu qui se forme à la surface du métal en fusion et qui est éliminé au cours du processus d'affinage. Nous avons également constaté que le laitier est utilisé dans d'autres domaines tels que la construction, avec le ciment et les matériaux de construction routière.

Levée de carbone

Leveur de carbone La quantité de carbone dans l'acier variant de 0 à 2,1 %, il est essentiel que cette étape soit réalisée avec soin, car elle permet d'obtenir différentes qualités d'acier, dont la dureté et la résistance ultime varient.

Revêtement réfractaire

Le revêtement réfractaire est le principal matériau utilisé pour protéger le four et s'assurer qu'il conserve la chaleur. Pour que le four reste entier, le revêtement doit résister à des températures élevées, à des réactions chimiques et à l'usure mécanique.

Applications courantes du four à arc électrique

Fabrication de l'acier

Le four électrique à arc est principalement utilisé pour fabrication de l'acier. Le four a une large capacité de production d'aciers au carbone et d'aciers alliés spéciaux. C'est grâce à ce contrôle précis de la composition que les fours à arc électrique peuvent produire à la fois de l'acier en vrac et des aciers spéciaux. En outre, les fours à arc électrique peuvent fondre le minerai de fer. Le minerai de fer est progressivement fondu dans le four, puis le métal est séparé.

Production d'alliages

Les fours à arc électrique permettent également de créer des alliages en mélangeant différents métaux. Un four à arc électrique peut être utilisé pour produire des alliages tels que l'acier inoxydable (chrome et nickel). C'est pourquoi il est facile de fabriquer des matériaux pour différentes industries telles que la construction, l'automobile et l'aérospatiale.

Prix des fours à arc électrique

Le prix d'un four à arc électrique varie en fonction de la capacité, des caractéristiques utilisables et de la technologie. Les mini-usines utilisent généralement des fours à arc électrique plus petits, dont le prix varie de quelques millions à plusieurs dizaines de millions de dollars, tandis que les grands systèmes entièrement automatisés peuvent coûter plus de $100 millions d'euros. D'autres dépenses telles que la consommation d'électrodes, l'électricité, les coûts de maintenance et l'utilisation de matières premières sont prises en compte.

Comparaison entre le four à arc électrique et les autres fours électriques

Four à arc électrique et haut fourneau

Source d'énergie

Par rapport aux fours à arc, les fours électriques à arc fonctionnent de manière plus souple en utilisant l'électricité comme principale source d'énergie, ce qui permet également d'inclure l'ER. Les hauts fourneaux, quant à eux, utilisent du coke, un type de charbon à forte teneur en carbone. À haute température, le carbone réagit avec l'oxygène du minerai de fer pour produire du fer.

Matières premières

Contrairement aux hauts fourneaux, qui utilisent du minerai de fer et du coke comme matière première, la ferraille est le principal intrant de la production d'acier par le four électrique à arc. L'aspect recyclage permet de réduire l'impact environnemental de l'aciérie électrique.

Four à induction et four à arc électrique

Le four à induction fonctionne sur le principe de l'induction électromagnétique, le four à arc électrique utilise l'arc électrique entre les électrodes. Le four à induction est utilisé pour les petites quantités de métal et permet d'atteindre une température précise, tandis que le four à arc électrique est utilisé pour la production d'acier à grande échelle.

Entretien des fours à arc électrique

Un four à arc électrique a besoin d'un entretien régulier pour fonctionner de manière sûre et efficace. Fourneau doublures doivent être contrôlées régulièrement, car elles s'érodent lentement au fil du temps en raison de leur exposition répétée au métal en fusion. Les électrodes doivent également être inspectées, car elles se dégradent avec le temps, en cours de fonctionnement. La surchauffe peut entraîner des dommages ou des pannes, et le système de refroidissement doit donc être surveillé pour éviter que cela ne se produise. Bien que ce régime d'entretien vous permette de prolonger la durée de vie de la révision et de prévenir les pannes soudaines, les plans et la mise en œuvre réels restent toujours incertains.

Tendances modernes de la technologie des fours à arc électrique

Conception de fours à arc électrique

Les conceptions récentes des fours à arc électrique ont mis l'accent sur une plus grande longévité, un débit plus élevé et une plus faible intensité énergétique. Des matériaux avancés sont utilisés pour prolonger la durée de vie du revêtement réfractaire et améliorer l'efficacité.

Efficacité des fours à arc électrique

L'efficacité est un facteur essentiel de la technologie moderne des fours à arc électrique. Il s'agit notamment d'un meilleur contrôle des électrodes, d'une plus grande stabilité de l'arc et de systèmes de surveillance sophistiqués qui fournissent une analyse du temps de fonctionnement afin d'optimiser la consommation et les pertes d'énergie.

Consommation d'électricité

La réduction de la consommation d'électricité est une étape importante pour rendre les fours à arc électrique plus économiques. Les fours à arc modernes intègrent des transformateurs et des systèmes de contrôle de la puissance afin d'obtenir des processus plus efficaces sur le plan énergétique, ce qui permet de minimiser les coûts globaux.

Consommation d'énergie

De nos jours, de nouvelles méthodes telles que l'extraction de la chaleur de la ferraille chaude avant l'entrée dans le four sont employées pour économiser l'énergie. Le préchauffage permet également d'économiser du temps et de l'énergie, établissant ainsi un processus de production plus durable en obtenant une fusion plus rapide en moins de temps.

Sécurité et performances antidéflagrantes

Des dispositifs de sécurité améliorés ont également été ajoutés aux fours électriques modernes, tels que des systèmes de surveillance des gaz et des conceptions antidéflagrantes. La sécurité étant une priorité absolue, de nouvelles normes sont également mises en œuvre pour minimiser les risques d'accident en cours d'exploitation.

Four à arc électrique Fusée avancée

Le four à arc électrique pour la fuséologie avancée est à l'étude, en utilisant les outils des technologies EAF pour l'espace. Par exemple, l'utilisation d'arcs électriques pour la propulsion ou le traitement des matériaux, ainsi que d'autres procédés de fabrication dans des conditions d'apesanteur.

FAQS :

Quelle est la consommation d'électricité d'un four à arc électrique ?

Les fours à arc électrique consomment beaucoup d'électricité, généralement environ 500 kilowattheures (kWh) d'électricité pour fondre une tonne d'acier. Toutefois, cette consommation varie en fonction du métal chargé, de la capacité du four et de la technologie de production.

Les poussières de four à arc électrique sont-elles des déchets dangereux ?

Oui, les poussières des aciéries électriques contiennent des oxydes de métaux lourds tels que le plomb, le zinc et le sodium, qui peuvent être polluants. Toutefois, pour réduire la pollution, les aciéries utilisent des technologies permettant de recycler les poussières en vue de leur réutilisation.

Conclusion

Aujourd'hui, le four à arc électrique est un outil agile de la sidérurgie moderne. Cette méthode crée un arc électrique qui fond et affine efficacement la ferraille d'acier, ce qui la rend parfaite pour le recyclage et les méthodes de production d'acier durable. Il peut s'agir de différents types de fours à arc électrique, de fours à courant alternatif, de fours à courant continu, de fours à arc électrique submergé, etc. en fonction de l'application concernée. Pour optimiser l'utilisation, les composants de la conception du four sont la coque du four, le revêtement réfractaire, le système de chargement et le système de refroidissement. L'empreinte carbone est faible, il nous permet de recycler de nombreux matériaux de manière efficace et flexible, et ce ne sont là que quelques-uns des nombreux avantages offerts par les fours électriques à arc. Au fur et à mesure que les technologies modernes et les innovations se développent, les fours électriques à arc continuent d'évoluer en termes d'efficacité, de sécurité et de durabilité, ce qui en fait une partie intégrante de l'industrie sidérurgique dans le monde entier.