El mecanizado de electrodos de grafito tiene como objetivo conseguir el tamaño, la forma y el acabado requeridos del producto. En la fabricación de productos de carbono y grafito, el procesamiento mecánico es una parte indispensable. La tecnología de procesamiento automatizado, los equipos y las herramientas de los fabricantes de grafito han mejorado recientemente.

Índice

Toggle¿Qué es el mecanizado de electrodos de grafito?

El mecanizado de electrodos de grafito es un proceso de fabricación que utiliza una máquina herramienta CNC para dar forma a los electrodos de grafito. Es una forma precisa y rentable de crear formas complejas con gran precisión. El proceso comienza con la preparación del electrodo de grafito, que se introduce en una máquina CNC (control numérico por ordenador). A continuación, la máquina dirige el electrodo de grafito hasta el lugar y la forma deseados, proceso que se utiliza para crear moldes exactos para diversos procesos de fabricación.

La importancia del mecanizado de electrodos de grafito

Desde el punto de vista del coste de producción, el ciclo de producción de los electrodos de grafito es relativamente largo, generalmente de 3 a 6 meses. El coste desde las materias primas hasta las piezas en bruto representa 95% del coste total, mientras que la mano de obra, los recursos materiales, y el tiempo que consume el mecanizado son mínimos. Si el producto se desecha o no se califica debido al procesamiento mecánico, es un desperdicio y no es rentable.

Importancia en términos de precios de las materias primas. La producción en bruto es sólo la producción de materiales, y el producto acabado sólo puede obtenerse tras el mecanizado. El material es mejor para los productos básicos, y la calidad del procesamiento e incluso la calidad del embalaje afectarán al precio del producto básico. Por lo tanto, prestar atención a la calidad del procesamiento mecánico puede mejorar eficazmente los beneficios económicos de la empresa.

Desde la perspectiva del uso por parte del cliente, si la precisión de procesamiento y el acabado del producto son bajos, no es propicio utilizarlo. Por ejemplo, si el electrodo de grafito se rompe o se cae en la conexión roscada del horno de arco eléctrico, se reducirá la eficiencia de la producción. Por lo tanto, los fabricantes de electrodos de grafito no sólo deben mejorar la calidad del producto, sino también la calidad del mecanizado.

Procesos de mecanizado de electrodos de grafito

En electrodo de grafito El proceso de transformación comienza con la preparación. Durante el conformado, la cocción y grafitización electrodos de grafito, su tamaño cambia y, a veces, algunas cargas se adhieren a la superficie, y su superficie es rugosa en este momento. Después de preparar los electrodos, se insertan en la máquina CNC y se orientan a la posición y forma deseadas.

A continuación, los electrodos de grafito se desplazan a lo largo de la pieza metálica de forma controlada, eliminando material del componente. El proceso puede producir piezas de alta precisión, según el tipo de máquina CNC y la calidad de los productos.

Herramientas y equipos de mecanizado

El proceso requiere algunas herramientas y equipos especializados. Esto incluye máquinas herramienta CNC con diversas herramientas de corte, como taladros, fresas y escariadores.

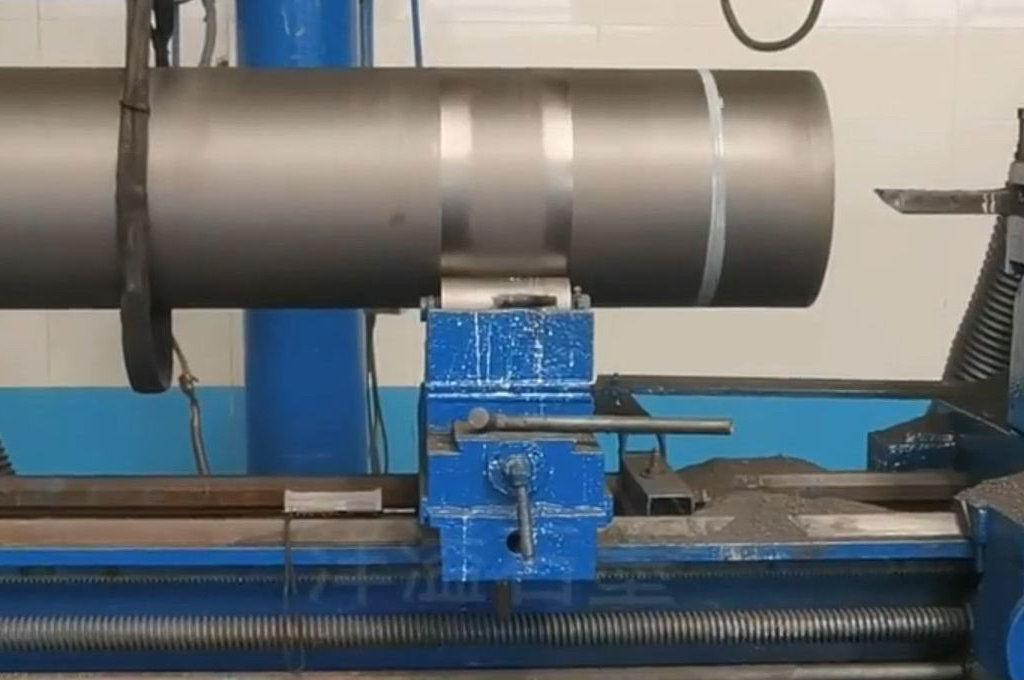

Los tornos CNC son especialmente adecuados para el mecanizado de piezas de eje o disco con formas complejas. Puede completar automáticamente el proceso de corte de las superficies cilíndricas interiores y exteriores, superficies de arco, roscas y otros procesos de electrodos de grafito.

El torno CNC tiene las ventajas de procesamiento flexible, fuerte versatilidad, operación conveniente y alta eficiencia. Puede satisfacer los requisitos de producción automática de cambios frecuentes de producto y se utiliza ampliamente en el procesamiento mecánico de productos de grafito.

Conclusión

El procesamiento de electrodos de grafito requiere equipos especializados, como máquinas CNC, fresadoras y herramientas de corte. A continuación, puede producir piezas precisas utilizando las herramientas y métodos correctos. Este proceso es crítico. Contamos con 15 años de experiencia y logros en la industria de los electrodos de grafito; si necesita electrodos de grafito, póngase en contacto con nosotros y le proporcionaremos una solución perfecta.