야금 산업에서 사용되는 탄소 및 흑연 제품의 종류는 크게 세 가지로 나눌 수 있습니다.

목차

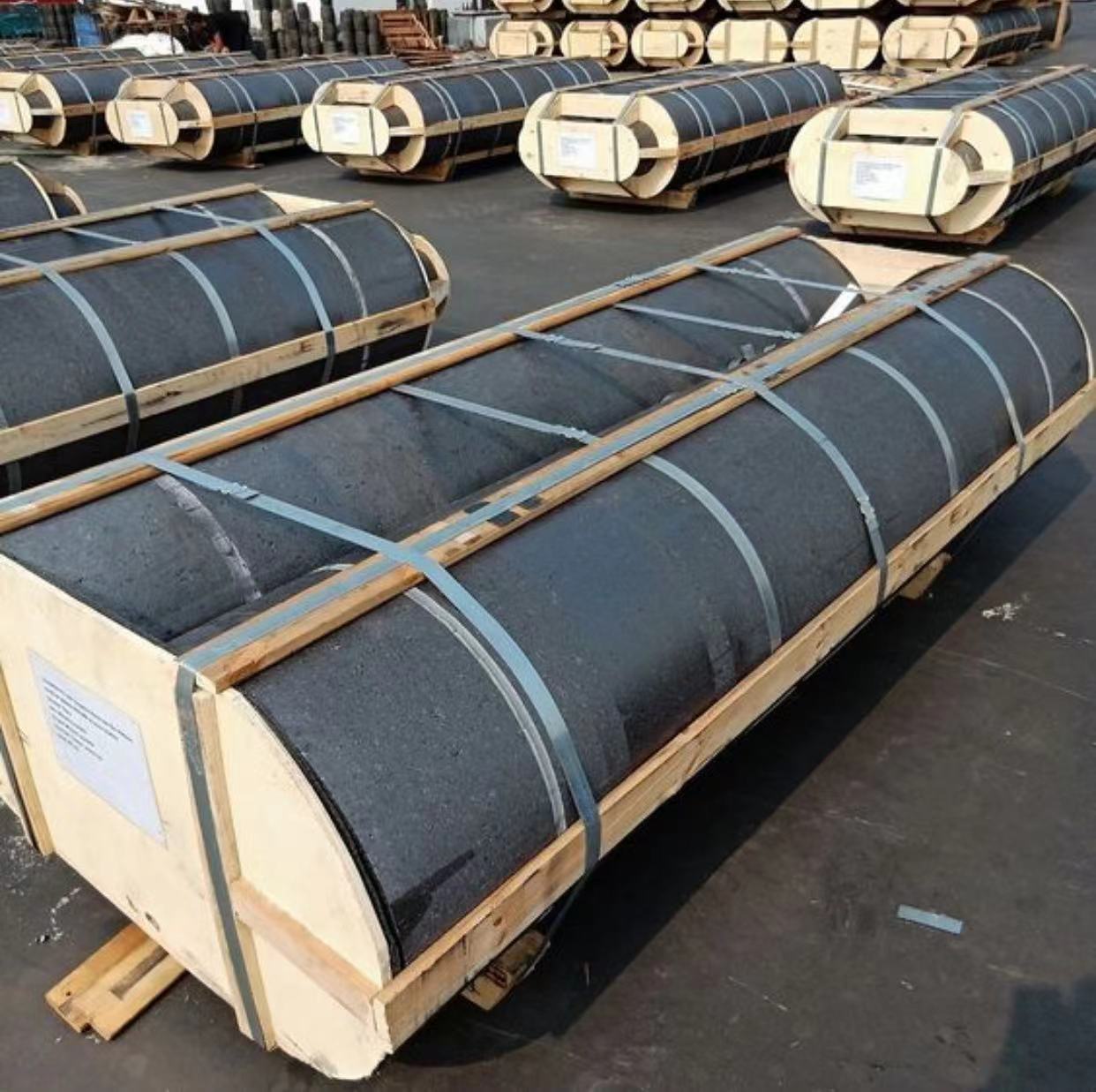

토글흑연 제품.

흑연화 제품 또는 인조 흑연 제품이라고도 하며 일반 전력 흑연 전극, 고전력 흑연 전극, 초고전력 흑연 전극, 초고전력 흑연 전극흑연 도가니, 흑연 보트, 흑연 몰드 및 기타 제품을 가공하는 데 사용되는 흑연 블록 및 고순도 흑연입니다.

이러한 제품은 석유 코크스와 아스팔트 코크스를 주원료로 콜타르를 바인더로 사용하고, 혼합, 압착, 로스팅, 흑연화 및 기타 가공 절차를 통해 비정질 탄소를 흑연으로 전환합니다.

일반적인 특징은 탄소 함량이 99% 이상이고 회분 함량이 일반적으로 0.5%를 초과하지 않으며 전도성이 우수하고 내열성이 우수하다는 점입니다. 산화 시작 시 온도가 상대적으로 높고 열전도율도 상대적으로 크며 내식성이 강합니다. 그러나 원료 준비에서 완제품까지의 생산주기는 일반적으로 약 3 개월이 걸리며 일부 고강도 및 고밀도 흑연 제품의 생산주기는 훨씬 더 깁니다.

탄소 제품.

성형 후 블랭크를 말하며, 섭씨 1300도 정도에서 구워지면 사용할 수 있습니다. 여기에는 전기로 카본 블록, 고로 카본 블록, 카본 전극, 카본 양극 등이 포함됩니다. 이러한 유형의 제품은 무연탄과 야금 코크스를 원료로 사용합니다. 천연 흑연 전극과 재생 흑연 전극은 천연 흑연 또는 인조 흑연 조각으로 생산된 전극으로, 로스팅 후에만 사용할 수 있습니다.

카본 페이스트 제품.

이 유형의 제품은 압착 및 가공 없이 원료(분쇄된 무연탄 또는 코크스 입자)와 바인더를 가열하여 균일하게 혼합합니다. 대신 가열된 혼합물의 페이스트를 블록에 주조하거나 정상적인 압력 하에서 용기에 넣기만 하면 사용할 수 있습니다. 전극 페이스트, 밀봉 페이스트, 굵은 심 페이스트, 미세 심 페이스트 등.

페이스트 제품은 용도에 따라 두 가지 범주로 나뉘는데, 하나는 합금철, 탄화칼슘, 황인 생산에 사용되는 전극 페이스트 전도성 재료와 같은 연속 셀프 베이킹 전극으로 사용됩니다. 다른 유형의 카본 페이스트는 알루미늄 제작에 사용되는 바닥 페이스트와 같이 카본 블록을 제작할 때 본딩 및 코킹 재료로 사용됩니다. 전해질 전지 탄소 블록. 페이스트 제품의 제조 공정은 비교적 간단하고 생산 주기가 짧으며 비용이 상대적으로 저렴합니다.