放電加工(EDM) スパーク・エロージョン(火花放電加工)とは、放電を利用して材料を除去する高性能の機械加工プロセスである。スパーク・エロージング、スパーク・エロージョン研削、または単にスパーク・エロージョンとも呼ばれます。CNC EDMスパーク放電加工機やポータブルスパーク放電加工機という定義で、同じ機器を目にすることがあります。これは、硬い材料を扱うときや複雑な形状を設計するときに非常に便利です。

目次

トグル

火花放電とは何か?

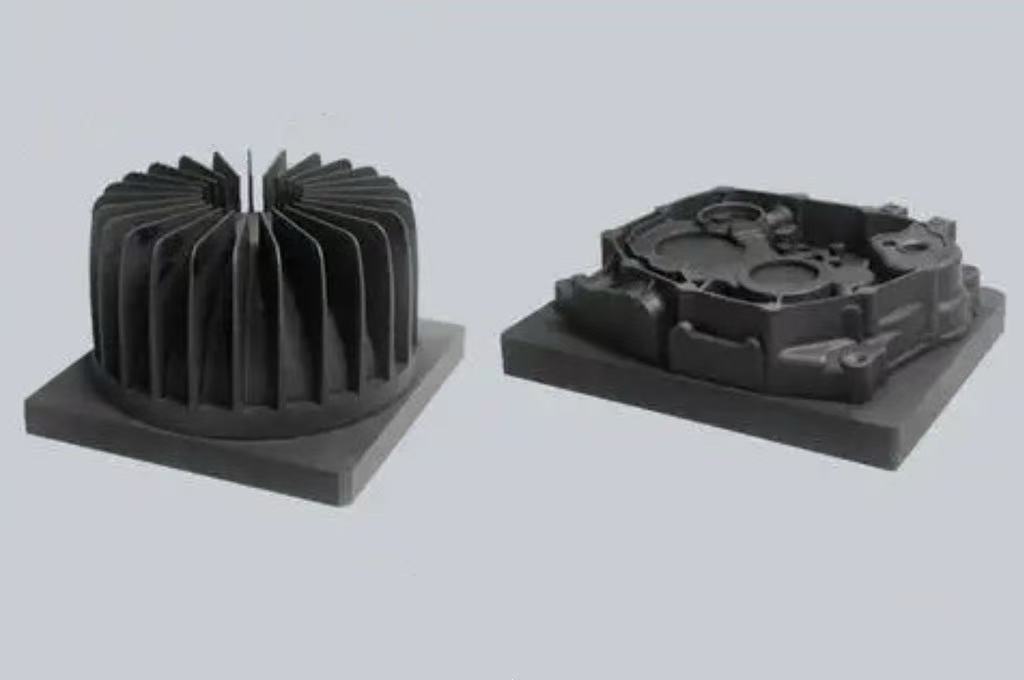

火花放電は、電気火花を使用してワークピースから材料を浸食する非接触材料除去プロセスです。このプロセスでは、ワークピースとワークピースの間の火花の形成を利用します。 黒鉛電極 と被加工物を誘電流体中に置く。これにより、材料の局所的な溶融と気化が起こり、サブミクロン単位の成形精度が可能になる。ラテルンはまさに火花放電であり、非常に硬い金属を陥没させることができる加工技術である。

火花放電の仕組み

火花放電加工では、グラファイト電極と被加工物の間に制御された放電が生じます。その仕組みはこうだ:

EDMグラファイト電極のセットアップ

誘電流体は、被加工物とグラファイト電極の間を冷却し、絶縁します。一般的な流体は、脱イオン水または炭化水素系オイルです。

スパーク・ジェネレーション

高電圧電流を流し、グラファイト電極と被加工物の間に電界を発生させる。両者が近づくと誘電体が破壊され、火花が発生する。

材料の除去:

電気火花の蒸気が表面に戻ることで、強い熱(12,000℃)が発生し、局所的に被加工物の材料を溶かしたり蒸発させたりする。

フラッシング

誘電流体が浸食された粒子を洗い流し、加工工程を汚染するのを防ぎます。

繰り返しだ:

これを素早く繰り返し、毎秒数千の火花を散らす。そして、希望の形になるまで繰り返す。

このプロセスの効率は、スパークギャップ、パルス長、電流強度、グラファイト電極材料からなる複数の要因に影響される。これらのパラメータを操作することで、さまざまな加工効果(表面粗さ、加工速度など)を得ることができます。

スパーク放電加工機を使用する理由

火花放電加工は、従来の加工プロセスと比較した場合、いくつかのユニークな利点があり、精密加工用途にしばしば選択されるプロセスとなっている。

高精度:高精度の複雑形状を製作スパーク放電加工により、精巧なデザインやミクロン単位で精密に加工された部品を簡単に作ることができます。

多用途:このプロセスは、チタン、タングステン、焼入れ鋼のような硬くて耐熱性のある材料から一貫した色を出すために使用することができます。これらの材料は従来加工が困難でしたが、EDMはこれらの用途でより高い能力を発揮します。

低ひずみ:このプロセスでは、機械的な力が加わらないため、デリケートな部品も無傷のまま加工できます。切削加工やフライス加工とは異なり、スパーク放電加工は残留応力や変形を誘発しません。

一貫性:一度加工パラメータを設定すれば、同様のコンポーネントを繰り返し生産しても高い信頼性が得られます。バッチ生産や大規模生産に最適です。

工具摩耗ゼロ:この工具は非接触で作動するため、標準的な工具に比べてグラファイト電極の摩耗が非常に少ない。

スパーク放電加工は、精度、汎用性、低ストレス性を統合した、あらゆる産業における優れたツールである。

一般的なアプリケーション

金型製作

火花放電は、複雑な金型、ダイ、切削工具の製造に使用される。硬い材料を精密に成形するため、工具や金型製作には欠かせません。複雑なキャビティから精密な切削工具まで、EDMがカバーします。

航空宇宙産業

航空産業では、高度な合金や複合材のような難削材の高精度加工が要求されることが多い。火花放電加工は、タービンブレードやエンジン部品のような高精度部品を、最高の性能を発揮するために必要な精度で製造することを可能にします。

自動車部門

スパーク放電加工は、高い精度が要求される部品を製造するために、自動車分野でよく採用されています。放電加工は、エンジン部品であれ射出成形金型であれ、大量生産が要求する細部と一貫性を提供します。

医療機器

医療分野におけるインプラント、手術器具、補綴物などのデバイスは、複雑な構成と精密な公差が要求されます。チタンやステンレス鋼の場合、火花放電は精度と生体適合性を保証します。

ジュエリー制作

ジュエリー制作には、精密さと一貫性を必要とする繊細で詳細な作品が必要です。スパーク放電を使用することで、ジュエラーは、より古典的な方法で作成することが困難であるか、または実行不可能な複雑なデザインを探求することができます。

さまざまなタイプの火花放電加工機

CNC放電加工スパーク放電加工機

CNC(コンピュータ数値制御)放電加工機では、加工プロセスの制御が高精度と自動化で行われる。高精度な加工や大量・迅速な生産に適している。

ポータブル火花放電加工機

ポータブルマシンは、大きなワークピースを簡単に持ち運ぶことができない現場での加工用途に最適です。さらに、修理の際に特に役立つ汎用性と手軽さを提供します。

手動火花放電加工機

単純な作業に使われる非常にシンプルな機械だ。値段は安いが、CNCほど精密で自動化されてはいない。

火花放電加工機の価格

CNCマシン

CNC放電加工機は、自動化や高精度などの特徴を持つため、これらの機械の中で最も高価である。価格は、$3万円以上から$30万円以上まで、モデルや機能によって異なる。 非常に高価なものは、航空宇宙や医療用に使用される非常にハイエンドの機械である。

ポータブルマシン

ポータブル火花放電加工機は比較的経済的で、価格は$5,000~$20,000です。また、機動性をさらに一歩高め、小規模な店舗や現場での加工プロジェクトに最適です。

中古機械

中古機の購入にはコスト削減の可能性がある。購入する前に、機械の状態を十分にチェックし、その機械があなたが考えているような機能を持っていることを確認する必要がある。中古機械は$3,000という低価格で購入できるが、新しい機械と同じ精度や機能を提供するわけではない。

火花放電加工機の予算は、イニシャルコストだけでなく、今後のメンテナンスコストや消費電力、グラファイト電極の交換なども考慮する必要がある。

近くのスパーク浸食の場所

あなたが火花放電サービスを必要とするときはいつでも、あなたは良い値であなたの近くから最高のものを取得する必要があります。ここにいくつかのヒントがあります:

検索エンジンを利用する:お近くのスパーク放電加工」や「お近くのCNC放電加工スパーク放電加工」などの検索キーワードを使って、お近くのサービス業者を見つけることができます。

レビューを見る:レビューや顧客の声を読んで、提供されるサービスの質をチェックする。

能力をチェックする:CNCマシンやポータブルマシンが必要な場合は、ショップが適切なマシンを持っていることを確認してください。

サンプルを依頼する:火花放電加工の品質と正確さを知るために、過去の仕事のサンプルを求める。

多くの製造工程では、精度の高い工具の製造が重要な鍵を握っており、スパーク放電加工サービスは、設計作業、修理、または単なる工具製造のいずれを必要とする場合でも、その答えとなります。

火花放電加工の利点

精密

高精度で、火花放電と呼ばれるさまざまな形状を取り出すことができます。繊細な宝飾品から複雑な航空宇宙部品まで、EDMが提供する精度は、まさに他では得られないものです。

汎用性

スパーク放電は、タングステン、チタン、カーバイドなどの硬質で耐熱性のある材料を除去することができる。また、より軟らかい金属に対しても優れた効果を発揮するため、さまざまな用途に使用できます。

最小限のストレス

非接触プロセスなので、ワークピースに機械的ストレスを与えません。この利点により、材料の完全性が維持され、壊れやすい部品やデリケートな部品でも変形を防ぐことができます。

再現性

パラメータが定義された後、EDMは一貫した精度で同一の部品を作ることができるため、均一性が重要な大型部品の生産に理想的です。

火花放電技術の未来

火花放電加工は、精度、効率、さらには持続可能性を高めるために開発が続けられており、常に進化し続けている分野です。

AIインテグレーション

将来の放電加工機では、AIの統合がより重要になり、より正確な加工が可能になり、より早く収益を上げることができるようになるだろう。しかし、AIは加工データを分析し、リアルタイムで調整を行い、プロセスを最適化し、黒鉛電極の消耗を減らし、精度を向上させることができるだろう。

エネルギー効率

多くの放電加工機ユーザーにとって、エネルギー消費は依然として大きな問題である。メーカー各社は、より低電力でありながら高品質な仕上げを実現する新技術を開発している。誘電流体や新しい電力供給システムのアップグレードも、より高い効率を実現しています。

先端材料

寿命、導電性、耐摩耗性を向上させるために、新しい黒鉛電極材料の研究が進んでいる。黒鉛と銅合金のこのような技術革新は、より良い性能とより長い電極寿命という大きな可能性を示している。

これらの技術革新により、火花放電加工の範囲と効果は拡大し、高精度の加工を必要とする分野でより有益なものとなる。

結論

火花放電加工は、硬い材料で精密な加工や精巧な形状が必要な一部の産業では、今でも使用されている。航空宇宙の世界から宝飾品製造まで、比類のない精度を誇ります。火花放電加工は、進歩とともに、より効果的で柔軟なものになっていくでしょう。EDMグラファイト電極を購入したい場合は、今すぐご連絡ください。