押出成形黒鉛は、新たな高性能材料として、そのユニークな特性と幅広い応用性により、多くの産業分野で頭角を現し、侮れない存在となっている。

目次

トグルⅠ.押出成形黒鉛の概要

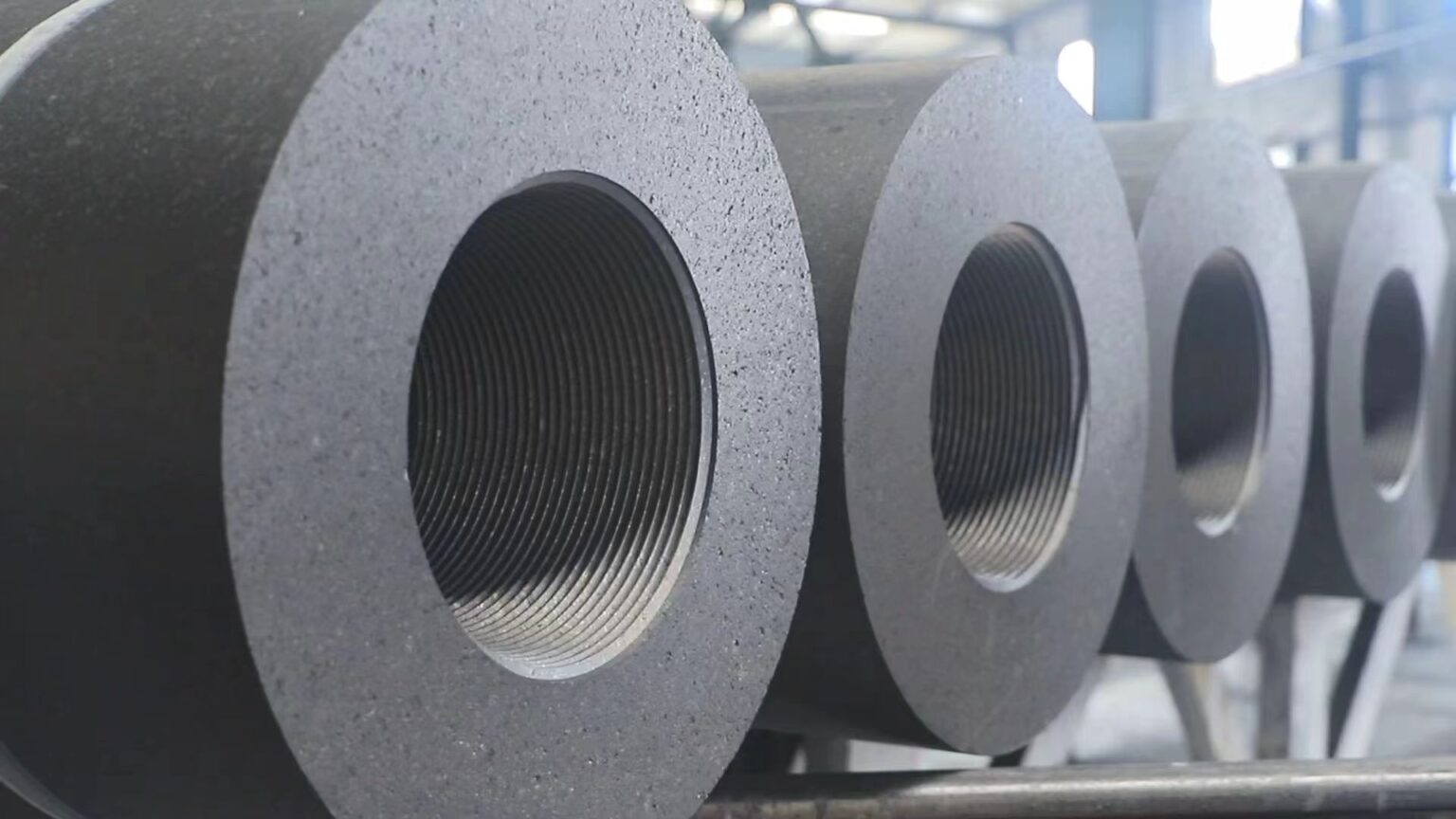

押出成形黒鉛は、黒鉛とバインダーの混合物を金型に押し込んで所望の形状に成形する押出成形プロセスによって製造される。

押出法は半連続生産である。一定量のペーストを加えた後、いくつかの製品(グラファイトロッド黒鉛ブロック、黒鉛材料)は連続的に押し出すことができるので、押し出し法の生産効率はプレスフィルム法よりもはるかに高い。

Ⅱ.黒鉛製品の特徴

- 吸着が良い。

中空構造のカーボンは吸着性に優れているため、水分や臭気などの吸着材としてよく使用される。

- 熱伝導率がよく、熱伝達が速く、均一に加熱でき、燃料を節約できる。

グラファイト製のベーキングトレイや鍋は素早く加熱され、調理物は内側からも外側からも均一に加熱されます。その上、加熱時間が短く、純粋な味が保たれ、食品本来の栄養が閉じ込められる。

- 化学的安定性。

常温での化学的安定性に優れた黒鉛は、強酸、強アルカリ、有機溶剤に侵されることがない。そのため、長期間使用しても黒鉛の損失はほとんどなく、必要なのはこすり洗いと洗浄だけである。

III.押出成形黒鉛の製造工程

- 材料の準備: 天然フレーク状黒鉛粉、アスファルトコークス、コールタールなどの原料を選択。

- 前処理: 粉砕、混合、予備酸化、化学修飾。

- ミキシングとプレス: 処理された原料を均等に混合し、特殊な装置を用いて高圧で加圧し、初胚を形成する。

- 焼結凝固: 初期胚を高温環境で焼結し、その構造を安定させる。

- 後処理: 切断、穴あけ、その他の加工工程を経て、目的の形や大きさの製品を作る。

IV.応用分野

- エレクトロニクス: 半導体製造における断熱材として。

- エネルギー産業: 原子炉用中性子減速材、電池材料。

- 冶金産業: 黒鉛鋳型、るつぼ。

- 化学産業: 耐食性部品、触媒担体。

– ブラシ: 良好な耐摩耗性と導電性を有し、導電性部品および摩擦部品としてモーター、発電機およびその他の機器に使用される。

- その他 航空宇宙、科学研究実験など

V.異なる黒鉛製造方法との比較

アイソスタティック・プレス・グラファイト:

利点:等方性、高強度、高密度、高純度、その他の特性。

アプリケーションのシナリオ:

半導体産業:グラファイトなどの単結晶炉熱電界部品の製造に使用される。 坩堝結晶成長の品質を保証するために、高温・高真空環境に耐えられるヒーター、電極などを使用する。

太陽電池産業:ポリシリコンインゴット炉の熱分野材料として、インゴットの品質と効率を向上させる。

EDM:高い導電性と良好な加工性を持つ。 アイソスタティック 押し出し黒鉛は、高精度の金型や部品を加工するための放電加工電極の製造に適している。

成型グラファイト:

利点:複雑な形状の製造が可能で、寸法精度が高い。

アプリケーションのシナリオ:

メカニカルシール分野:ポンプシールリング、コンプレッサーシールリングなど、あらゆる種類のメカニカルシールリングを製造している。

燃料電池燃料電池の製造に使用されるバイポーラ・プレートは、その優れた導電性と耐食性により、燃料電池の性能と寿命の向上に役立っている。

人造黒鉛:

利点:硬度、耐摩耗性、導電性など、ニーズに応じて特性を調整できる。

アプリケーションのシナリオ:

リチウム電池:として 陽極 リチウム電池の材料で、サイクル性能と比容量が高い。 つまり、電池のエネルギー密度と寿命を向上させることができる。

潤滑剤人造黒鉛は摩擦係数が低いため、航空宇宙、自動車、その他の用途で高性能潤滑剤として使用され、摩擦や摩耗を低減します。

Ⅵ.押出成形黒鉛製品の正しい使用方法

- 環境条件のコントロール

- 温度:ほとんどの押し出しグラファイトは、3000℃までの無酸素環境では安定した状態を保つことができるが、酸素を含む環境では、酸化を防ぐために400℃以上の使用温度は避けるべきである。

- 腐食性媒体:特定の酸塩基溶液やハロゲン化合物はグラファイトを侵す可能性があるため、使用前に媒体の適合性を確認すること。

- 湿度:グラファイトは湿気に強いが、湿気は電気的特性に影響を与える可能性があるため、保管時は乾燥した状態に保つこと。

- 加工と設置

- 切断、穴あけなどには、不純物の混入を避けるため、非鉄工具を使用すべきである。

- 衝撃や重力による亀裂を防ぐため、取り付け時の取り扱いには十分注意してください。

- クリーニングとメンテナンス

- 表面のホコリを取り除くには柔らかい布やブラシを使い、硬い掃除道具で表面を傷つけないようにしてください。

- 摩耗や損傷の兆候がないか定期的に点検し、老朽化した部品や損傷した部品を適時に交換する。

- セキュリティ対策

- 通電部品と接触して使用する場合は、電流の過負荷を避けるために、よく接続されていることを確認してください。

- 操作時、特に高温または危険なガス環境での作業時には、適切な個人用保護具を着用してください。

- 保管に関する推奨事項

- 化学薬品や直火を避け、涼しく乾燥した場所に保管すること。

- 長期間ご使用にならない場合は、環境要因の影響を軽減するため、防湿梱包をご利用ください。

- 注意事項

- グラファイト自体は可燃性ではないが、特定の条件下では自然発火を起こすことがある。例えば、高速摩擦による火花や、酸素の多い環境で高温に長時間さらされた場合などである。

- 酸化を促進したり、安全上の問題を引き起こす可能性があります。

VII.現代産業における将来の発展可能性

現在、押出成形黒鉛は密度や強度が向上しているだけでなく、耐食性や熱安定性も最適化されている。今後も市場の新たなニーズに応えるべく、進化を続けていくだろう。

今後、押出成形黒鉛の開発は、技術革新と応用分野の拡大に一層重点を置くことになる。半導体産業における高純度黒鉛材料の需要が増加するにつれて、押出黒鉛は純度の向上と加工精度の向 上に重点を置くようになる。技術的には、押出黒鉛の熱伝導性と機械的強度を向上させることに重点が置かれ、例えば、その特性を向上させるための新しい複合材料の開発が行われる。さらに、持続可能な開発目標の進展に伴い、押出成形黒鉛の生産と応用は、環境に優しい材料の使用と設計に一層注意を払うようになる。同時に、生産工程におけるエネルギー消費と廃棄物の排出を削減する。