EDM graphite is a special type of electrode material used when performing the EDM process. It is a binder which imparts to the metals, the character of being true as well as extremely complex shape. EDM graphite functionally shapes again by using ed electrical discharges to erode the velocity of the workpiece by means of ingle sign sequence in rate as desired. Due to its promise to be highly conductive and resistant to wear, this material is from which this operation should be carried out.

It is constructed of durable ultra-fine graphite, ensuring that it remains stable despite the thermal shocks imposed by electrical discharges. Precision in a workpiece uses these electrodes.

Graphite rods are long cylindrical and made of fine-grained graphite and are used as electrodes in the electrical discharge machining (EDM) process. These types are often chosen for precision over many years of usage and sculpturing intricate shapes.

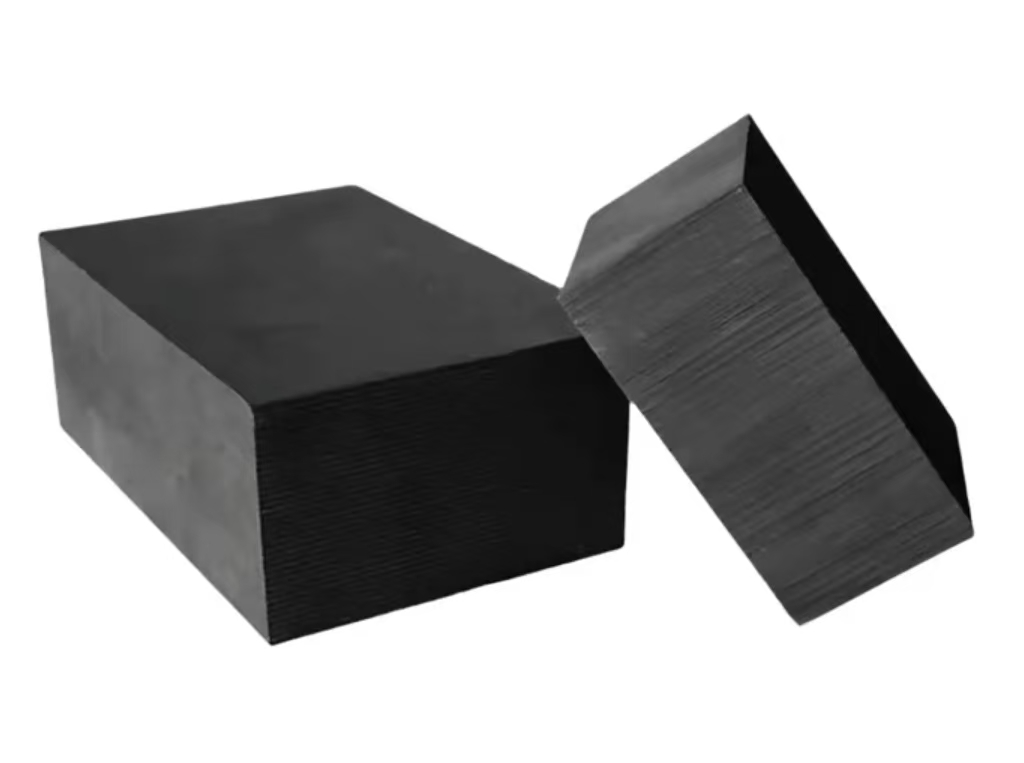

These blocks are specifically designed for EDM use, larger and thicker than rods making them suitable to generate larger electrodes. These are generally machined into custom shape depending on the requirement of a project.

Jinsuncarbon EDM graphite is widely appreciated for its unique properties well suited for your machining. These include:

Good conductive property is important to do machining with EDM. Graphite has great conductivity, which is ideal for allowing the electric discharges to run through the electrode and into the workpiece.

Graphite also has good heat resistance which plays a significant role at the high temperatures involved with machining. It retains stability during the intense heat of EDM processing.

Graphite for EDM compared to other materials is considered a low wear rate. It is more durable while machining, so we need not replace it frequently.

Graphite is also relatively easier to machine than metals, enabling better designs with finer details. Its very easy to form it into the electrodes for complex machining jobs.

EDM graphite is widely used to produce intricate details in metal mold for mold die manufacturing. The precision it provides for carving shapes makes it the most appropriate tool for high-precision industries such as automotive and aerospace.

Graphite for EDM machining of high precision tooling parts This is the top-of-the-line in its type when it comes to industrial production, for the machine executes machining with high precision and great efficiency.

Because a lot of medical devices and aerospace smoothed external components must be created using extremely exact requirements, EDM graphite grades is normally chosen to fabricate such parts. This feature manufactured these components with complex geometries and tight tolerances, which are essential for parts used in such industries.

EDM graphite manufacturing starts from excellent quality graphite raw material. The steps involved are:

Discover FT graphite to use for EDM machining, you are going to require graphite with very high density and purity level as this will give you the best conductivity and wear.

After the right material has been chosen, graphite for EDM is molded into the required pieces that includes rods, blocks and electrodes among many others. This is achieved via mold casting or milling methods.

Once the general form is developed, the graphite is machined to exacting dimensions. Grinding cutting drilling and other machining processes are carried out to refine the electrode shapes.

After forming, the electrode will receive finishing to ensure that it meets specification. EDM graphite has to machine well, and therefore the need for quality control.

How it performs depends on the particle size of the graphite. Finer particles mean finer surface finish, while coarser ones can give you higher speed achieving finishes. Select Per your accuracy needs.

The machinability of various EDM graphite grades differs from each other. While some grades are easier to machine others have higher wear resistance. It all depends on your project’s needs.

The control over the size and shape of the electrode is important for precision machining. With custom EDM graphite electrodes, you can choose from different grades and sizes to meet your special workpiece needs.

Different industries will be best suited by different type of materials. High-purity EDM graphite is best for industries in which precision is paramount, including aerospace and medical.

Copyright © 2018. JINSUN New Material Technology., LTD All Rights Reserved.